Bubble Emission Leak Testing Systems

A Bubble Emission Leak Testing System is a device that has the ability to detect, locate, and somewhat quantify a leak through the emission of bubbles.

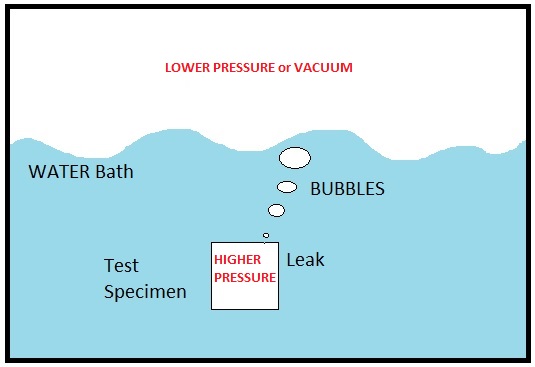

The system consists of two main components. The first component is a device which generates a pressure differential between the inside of the specimen and the outside of the specimen. This pressure differential will start to drive the internal gas or liquid of the specimen from the higher pressure (inside of specimen) towards the lower pressure (outside of specimen) through a leak path. This pressure differential is accomplished in two ways:

1. Internal Pressurization through the insertion or connection of a pressure probe (pressurized line). This means that the internal pressure is greater than ambient air pressure

2. Vacuum through the placement of the specimen inside a vacuum chamber. This means that the pressure inside the specimen is ambient and the pressure outside of the specimen is less than ambient.

The second component of a Bubble Emission Leak Testing System is a submersion fluid. This fluid, which in most cases is water, will enable the operator to detect the bubbles emitting from a leaking specimen. The submersion fluid can sometimes be an oil, or acidic bath, or other liquid substance. The fluid acts a medium enabling visual detection of air bubbles.

Please check our Vacuum Bubble Emission ASTM 3078 Leak Testing Systemsz and our Internal Pressurization ASTM F2096 Leak Testing Systems.