Phototesting of different materials through vacuum, airflow, and laser

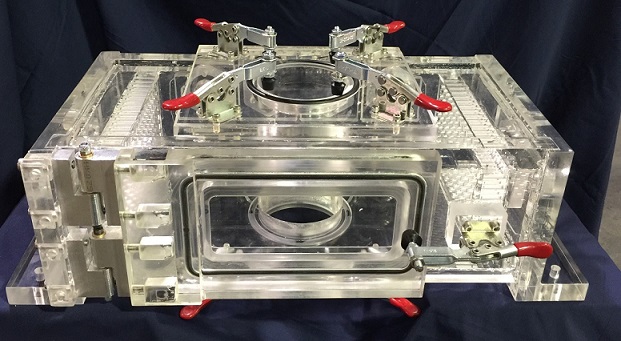

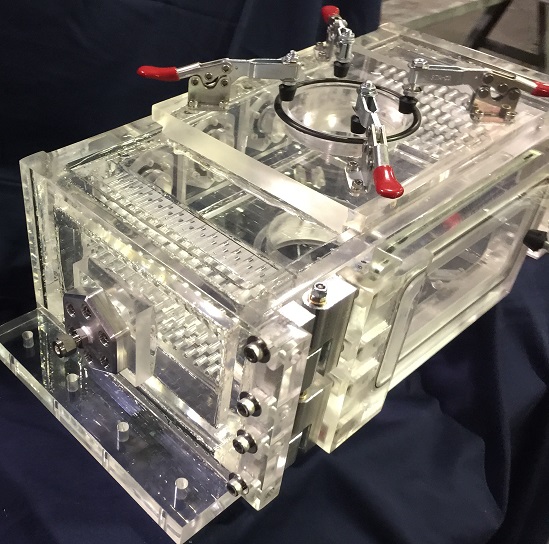

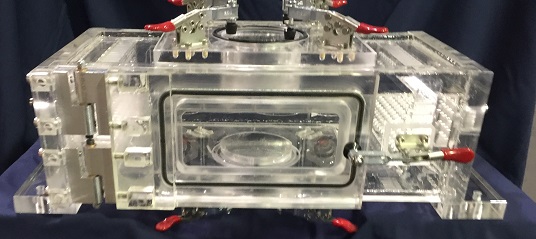

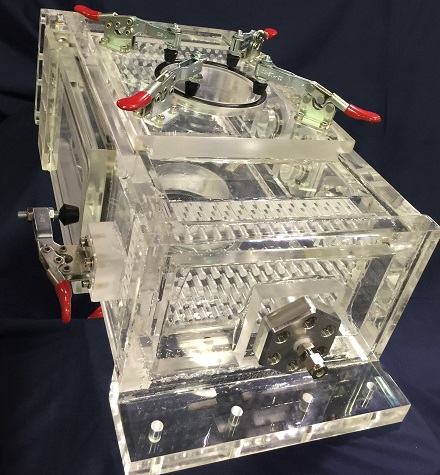

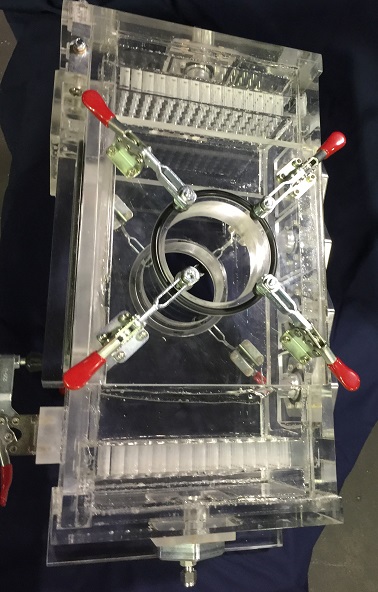

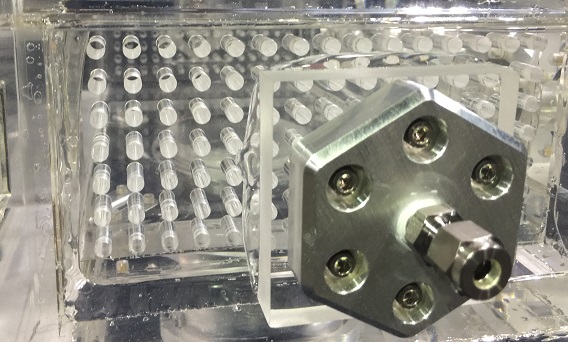

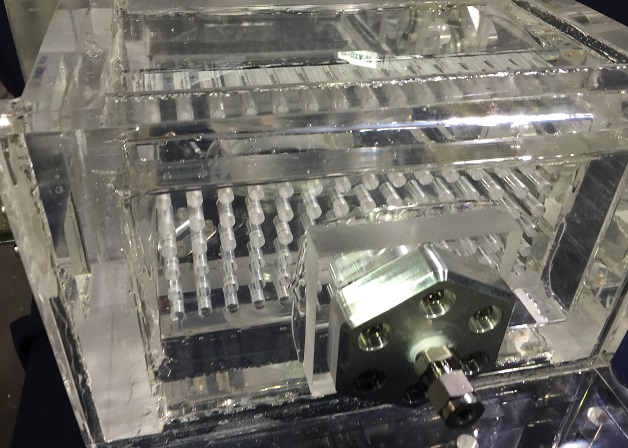

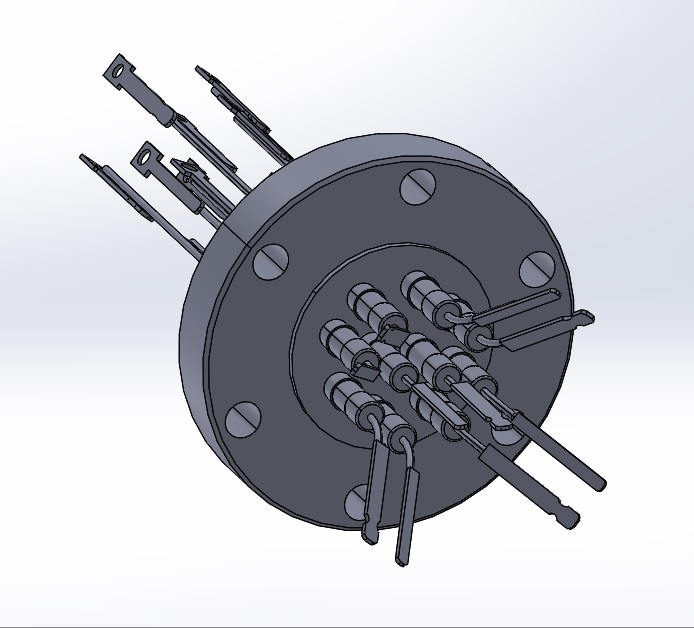

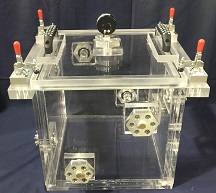

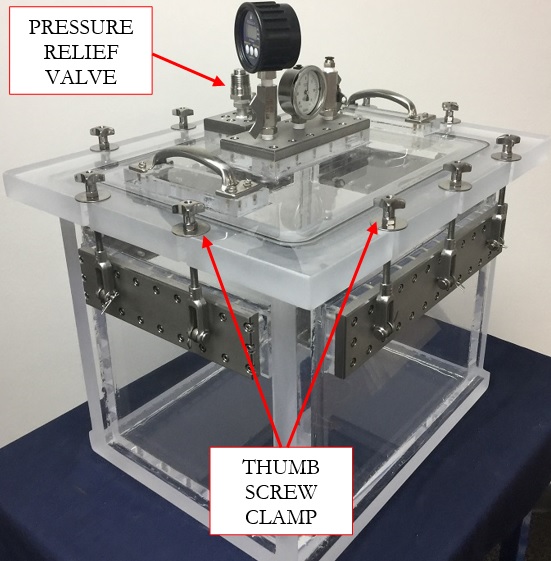

This was a fun project as it involved a custom chamber with the following items: a front door, two airflow diffusers (inside plate with lots of holes), four spare ports, top hole and bottom hole with a gasket to allow for different specimen to be placed, clamped, and tested.

Our client did not tell us much about the details of the project, all we got were the design input requirements and a napkin sketch.

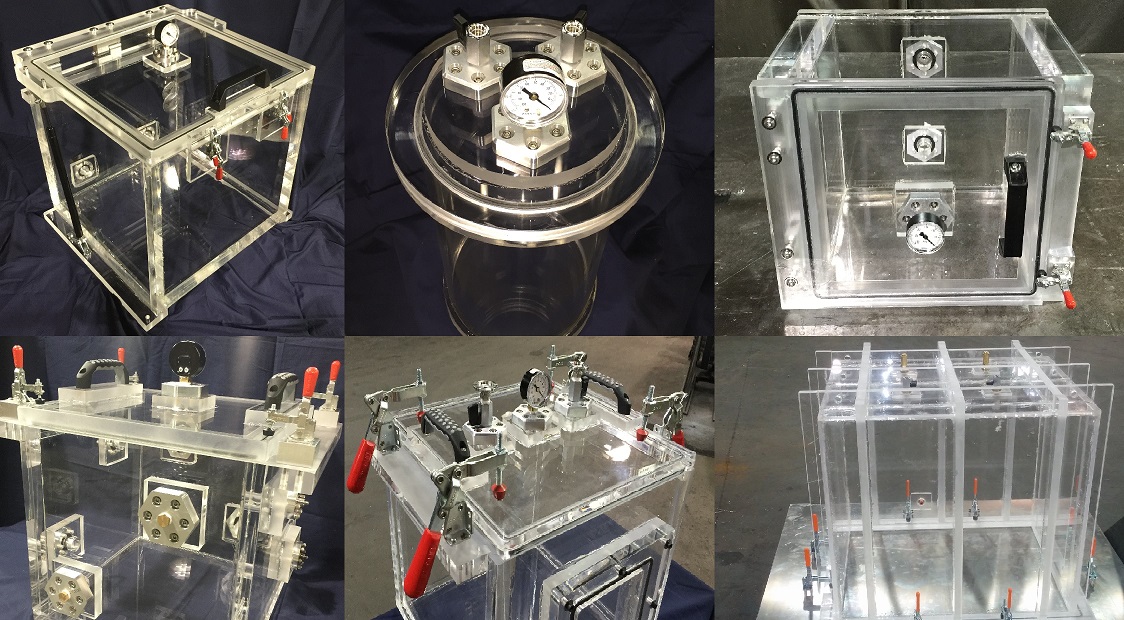

What you see is an acrylic vacuum test chamber. We still have no idea what this chamber is used for, we didn't dare to ask; but it doesn't matter because it was a fun and challenging project and we are happy we were able to help them out.

We have many more resources on our website that you should check out

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers