Did you know that you can use an Acrylic Vacuum Chamber, a vacuum pump, and a digital vacuum gauge to perform Altitude Testing of Batteries and Capacitors according to the MIL Standards 202G, Test Method 105G? The Department of Defense developed a wide array of testing and operating procedures in the 1950 and 1960 which are called “MIL Standards”

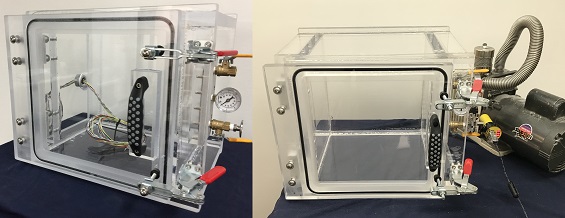

This particular test is the reduced barometric test which utilizes a vacuum chamber with pump to simulate the effects of lower pressures applied to test specimen by higher altitudes. The pressure inside the chamber can be set to correspond to a specific altitude at which your parts will be tested. The two most popular ways products can be tested inside a vacuum chamber are either to place them inside the chamber and pull the vacuum to correspond to a specific altitude (Right Image). Or Place them inside of the chamber, set the pressure to correspond to a specific altitude, and then power the devices up to see if these will still function properly. To do that, you will need a vacuum feedthrough.

Our client needed several vacuum chambers with different configurations for different test protocols. One chamber was fitted with a 18-wire Vacuum feedthrough; the other chamber was fitted with a digital vacuum gauge to enable higher accuracy vacuum display; hence, higher accuracy altitude display.

Since Batteries and Capacitors are sealed with internal fluids or proprietary sealants, these must be tested inside a vacuum chamber. As the vacuum is increased, the seal may fail due to increased pressure differential between inside the battery or capacitor and outside of the battery or capacitor. Our client needed a way to power up their batteries and capacitors in order to confirm the correct operation of the components. In addition, powering up the electronic test specimen allowed our client to test the cooling ability of their products since reduced air pressure can impede or alter the heat profile of the components which can potentially lead to failures.

If you are looking to test your batteries or capacitors according to the MIL Standards, Contact Us to learn how we can improve your testing procedure and hence improve overall product quality.