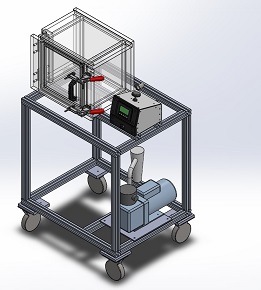

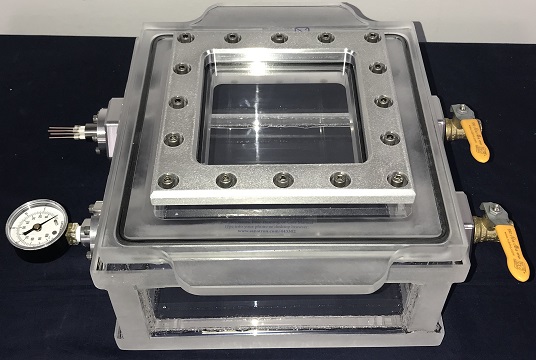

Altitude Package ASTM D6653 Leak Testing System, Clear Acrylic Vacuum Chamber, Front Load, 22 inch cube

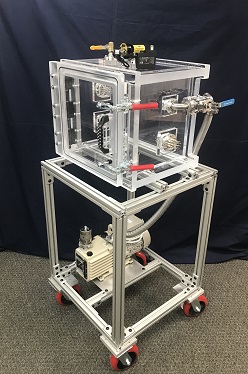

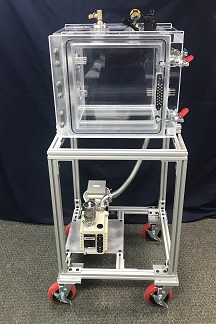

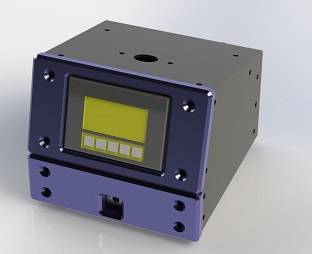

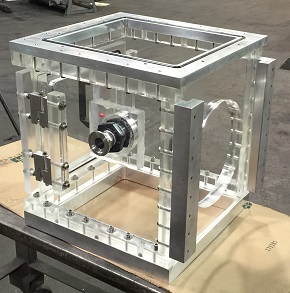

Additional Vacuum Chamber, Pump, or Controller Images

Check out some of our portable vacuum chamber and pump systems. All our vacuum chambers, vacuum controller, vacuum systems, or anything else that we make can be customized to your requirements and specifications. Contact us if to learn how we can build you a fantastic vacuum system.

Product Specifications

Features

Description

Sanatron Altitude Package Quality Testing System is a complete Turn-Key System. This system is specifically designed and built to enable you to perform the ASTM D6653 - Standard Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method. Included are a Front Door Loading Crystalline Clear Acrylic Vacuum Chamber with the inside dimensions of 22 inch Wide, 22 inch Deep, and 22 inch High, an Oil-Free Dry Vacuum Pump, an Altitude Controller (made by Sanatron) featuring an intuitively easy to use HMI screen with several programmable options, and a fully portable cart/skid with lockable swivel casters enabling you full mobility at your facility - all components are fully connected and ready to go ? you will not need to assemble anything at your facility.

The ASTM D6653 protocol is a guide protocol that will enable you to test the effects of higher altitude on the package integrity of your products. During transport, packages will experience changes in altitude, hence the outside pressure will vary. If your packages are packaged at sea level and if your product is sealed, the internal pressure will stay at about 15 psig. As your products are transported, the change in altitude will correspond in a change in outer pressure. This will create a pressure differential causing your products to swell, expand, or even burst or get damaged. You can test heat sealed packages, batteries, containers, encapsulated products, ultrasound sealed specimen, medical equipment and devices, or anything else that you would want to test for integrity at higher altitude ? this includes transport by air or truck.

Our ASTM D6653 Product Quality Testing System will allow you to test your products for seal and product integrity. The mode of operation is as follows. (1) load your test specimen into the vacuum chamber, (2) close the vacuum chamber and clamp the door, (3) press the START button and the altitude controller will run the test for you automatically ? the test consists of increasing the altitude at about 1000 ft or 305 m for every 30 to 60, after the desired altitude level of 16,000 ft has been reached the altitude controller will now hold the vacuum at this level for the 60 minutes. Keep in mind that you can program your controller to a higher or lower altitude equivalent ? how high of an altitude you can go is dependent on the maximum vacuum of the vacuum pump. Than, the vacuum will slowly decrease at a rate of 1000 ft or 305 m for every 30 to 60. After the vacuum/pressure level has reached ambient pressure, the altitude controller will signal to the user that the test is complete. (5) open the door and inspect your test specimen. And yes, it is as easy as described. Oh and before we forget, some of most popular customization options to this system include additional shelves for more testing space. Contact us to let us know how many shelves you would like to add to your chamber.

We have many more resources on our website that you should check out

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.