CRVpro 16, 115V,60Hz 1Ph, NW25 with Flare Fitting for Refrigeration Duty

Product Specifications

Features

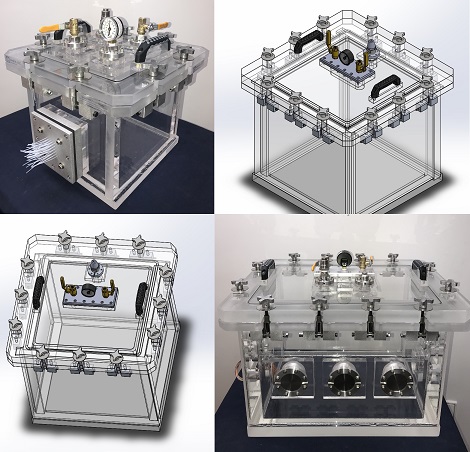

Description

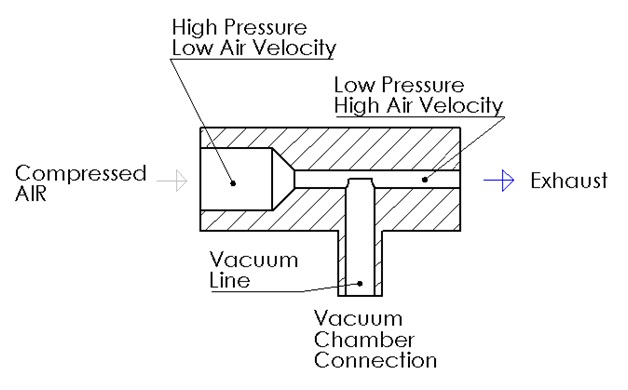

The brand new Welch CRV Pro 16 Model 3161-02 direct drive Rotary Vane Vacuum Pump. One advantage of the CRV Pro Vacuum pump is that has an much more increased reliability and longer service life vs other high performance, heavy duty vacuum pumps. The reason this rotary vane vacuum pump can achieve much higher robustness and reliability is because of three main point. First, this vacuum pump will run 10 Degrees Celsius cooler than other comparable pumps which means that the corrosion and wear and tear is slowed down. Second, this vacuum pump has 40% larger oil capacity than comparable vacuum pump, this larger oil capacity will further dilute any corrosive constituents inside the vacuum pump. Third, this vacuum pump has a chemical resistant coating in the oil case and pump module which means that all non-moving parts are protected from corrosion. Furthermore, the CRV Pro Rotary Vane Vacuum Pump consumes up to 36% less oil than other comparable vacuum pumps ? this decreases the service and maintenance requirements of this vacuum pump.

The CRVPro Vacuum Pump includes all feature you need from a direct drive rotary vane vacuum pump such as Quick Flange Intake and Exhaust, Fastening Holes, Gas Ballast, Force Oil Lubrication, Anti-Suckback valve, and thermal overload protection

Common Applications include but are not limited to: degassing, vacuum ovens, vacuum concentrations, vacuum leak testing, altitude simulation, freeze drying, electronic equipment testing, and other vacuum applications. Please note that Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr. Contact us to discuss your vacuum applications.

Did you know that we carry a many more products?

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.