Did you know that gasses and liquids and even solids behave differently at different absolute pressures? For Example, water will start to boil at a lower and lower temperature as the pressure is decreased. Water can boil at room temperature if the pressure is decreased to 20 Torr of absolute pressure. Other phenomenon which can happen is that materials can fuse together or weld in high vacuum.

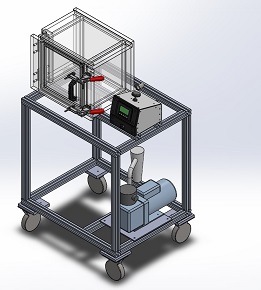

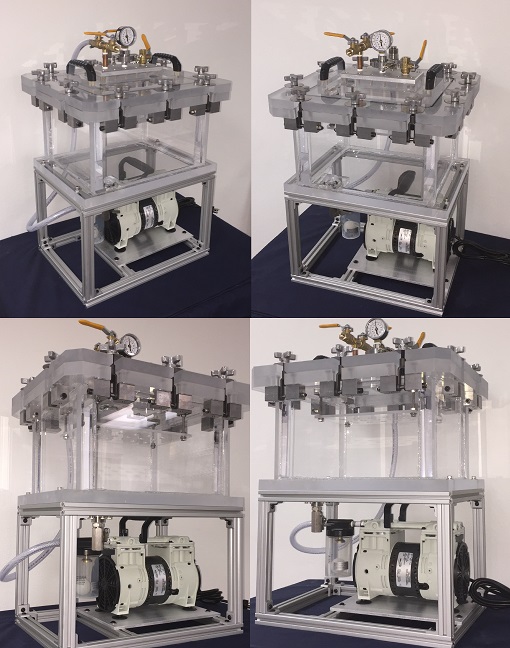

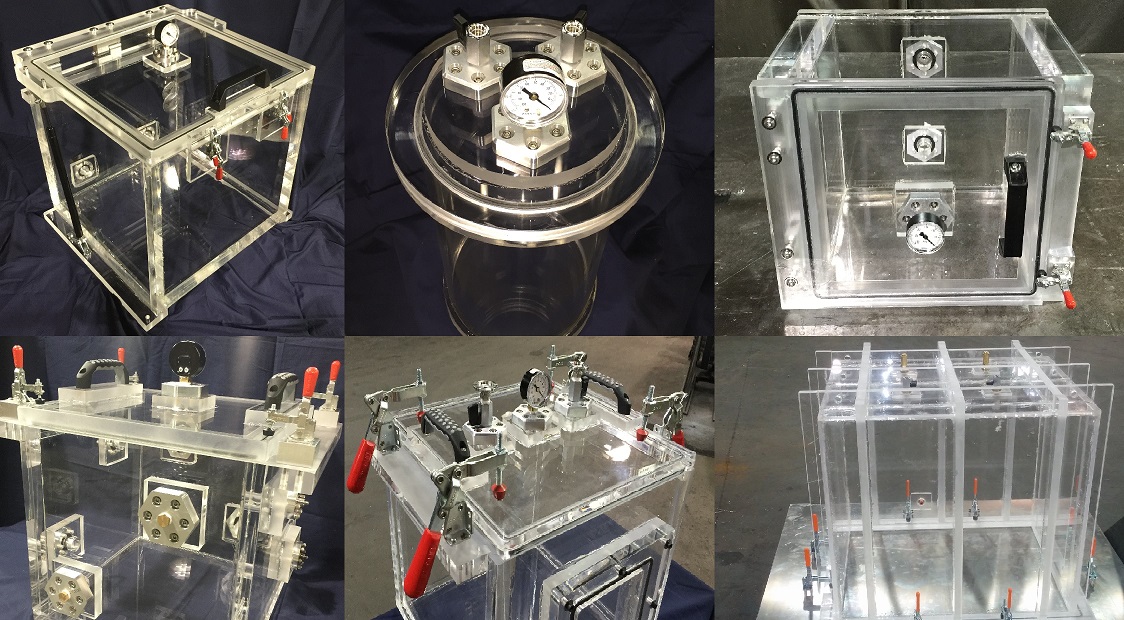

Our client is in academia performing research on Gas Phase and Liquid Phase Experiments. They required a large vacuum chamber that has a spring supported lid. The also asked us to provide them with an electrical NEMA-15 outlet so that they can power up some of their electrical devices inside of the vacuum chamber without compromising the vacuum.

In addition to the above, they requested a 25 Multipin Vacuum Feedthrough. This feedthrough along with the electrical outlet are placed on the rear wall. Finally, they requested 6 x 1/2 inch NPT liquid or gas vacuum feedthroughs that are placed on the remaining 4 exposed walls of the chamber. We plugged these feedthrough ports so that our client is able to remove the plug and hook up their liquid or gas line onto the port and run it into the vacuum chamber. The port is threaded from both inside and outside.

Are you conducting phase experiments on liquids or gasses? Contact Us

You may be interested in some of our other items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers