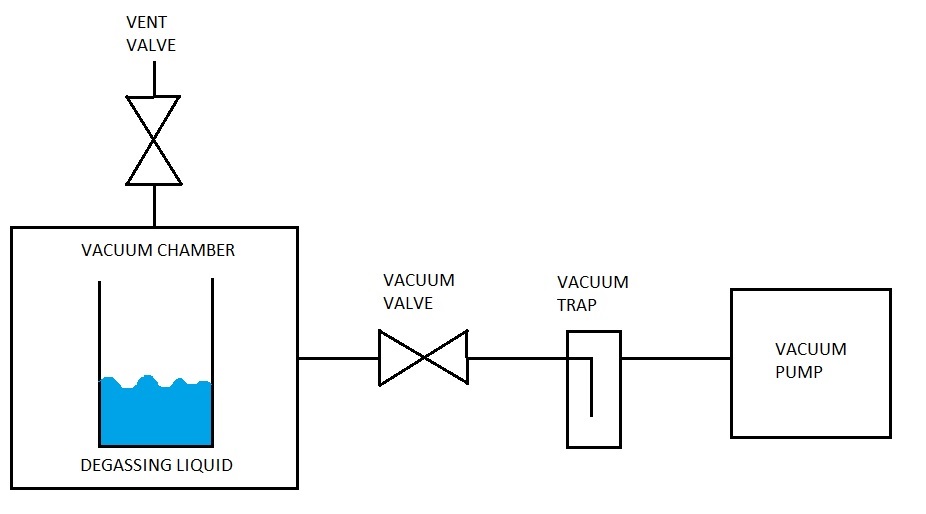

Degassing vacuum chambers are used to remove dissolved gasses from a liquid. A degassing system is especially useful when dealing with molds or epoxies. A typical degassing system setup is made of a vacuum pump (to pull the vacuum), a vacuum chamber (to create vacuum environment), vacuum valve (between pump and chamber), vent valve (to vent the vacuum when done), and a vacuum trap. The vacuum trap filters and prevents any liquid residue from getting into the vacuum pump.

The more viscous the fluid is, the higher the vacuum needs to be for effective degassing. Therefore it is recommended to use a two stage vacuum pump with the ability to pull a vacuum of better than 28.5 inHg (36 Torr, 5kPa). The higher the vacuum pump airflow rate, the faster you will be able to pump down to your required vacuum level; hence the faster the degassing process will be.

Note that the liquid will expand during the degassing process and therefore your liquid holding cup should be filled roughly one third with liquid where two thirds should be left as the expansion space. However, it is always advised to experiment with your degassing system setup (and liquid) to determine the appropriate filling volume, degassing time, and vacuum level so that you can optimize your degassing procedure.