Are you unsure how to test for seal integrity of your package closures? How do you know you have a good product? Would you like to know how to test your package for closure and seal quality?

If you answered yes to one of these questions, you are on the right track. We have some resources to guide you on how to test your products for seal failures. Click on the links below to learn more about how to package test for the following:

How to Test Seal Integrity of:

We have many more resources on our website that you should check out

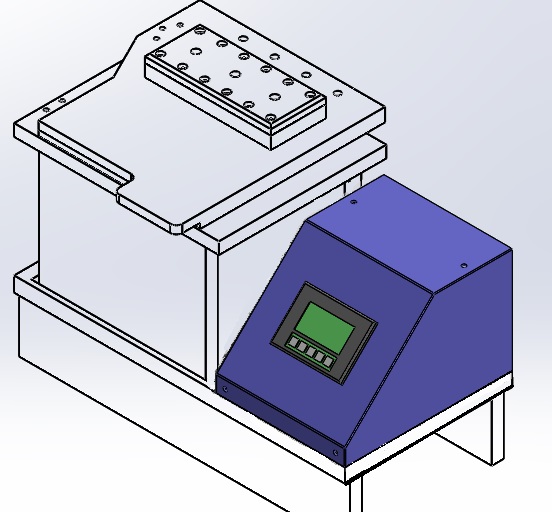

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.