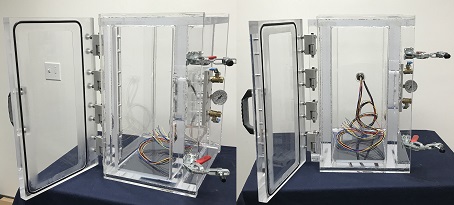

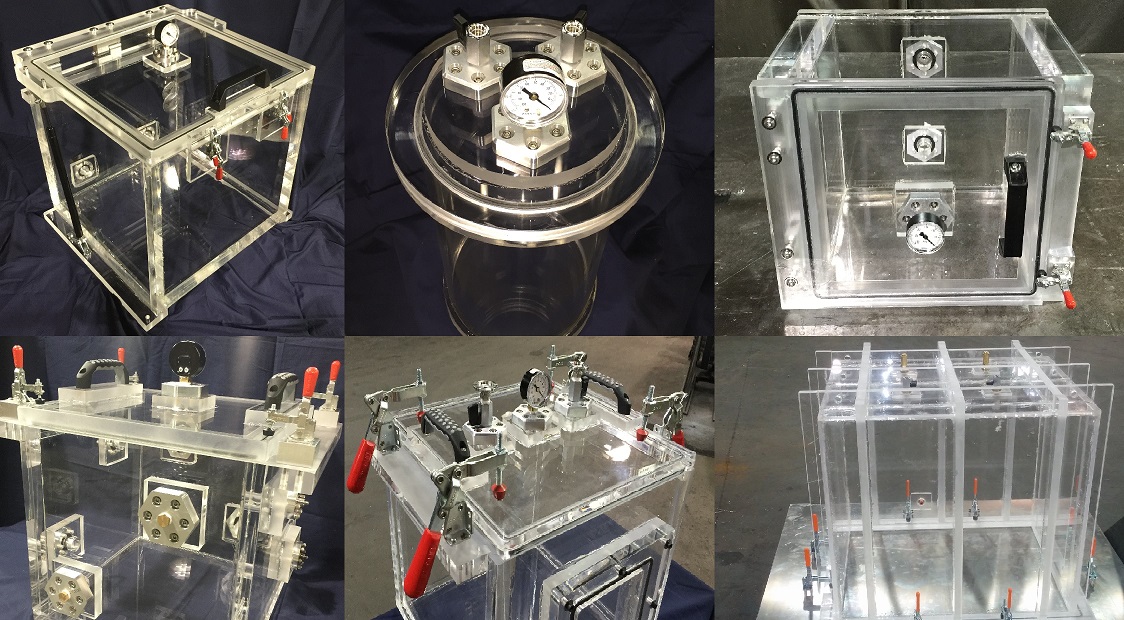

It is vital to perform Production Quality Control testing on Automotive components during manufacturing. Our Client used the chamber above to perform tests on several automotive components coming of the production line.

The Chamber you are looking at is about 12 inch Wide, 18 inches Deep, and 20 inches High. This is a custom design and slight modification from our regular front load, hinged door model. Our Client was also looking to connect and run electricity from the outside towards the inside of the chamber and wanted to keep the vacuum constant. An electrical vacuum feedthrough allows the operator to run electrical signals into the chamber without compromising the vacuum levels. The feedthrough will work even at low or high vacuum testing operations.

Are you in the automotive industry and looking for a good vacuum system? Contact Us to see how we can be of service.

Similar Items

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers