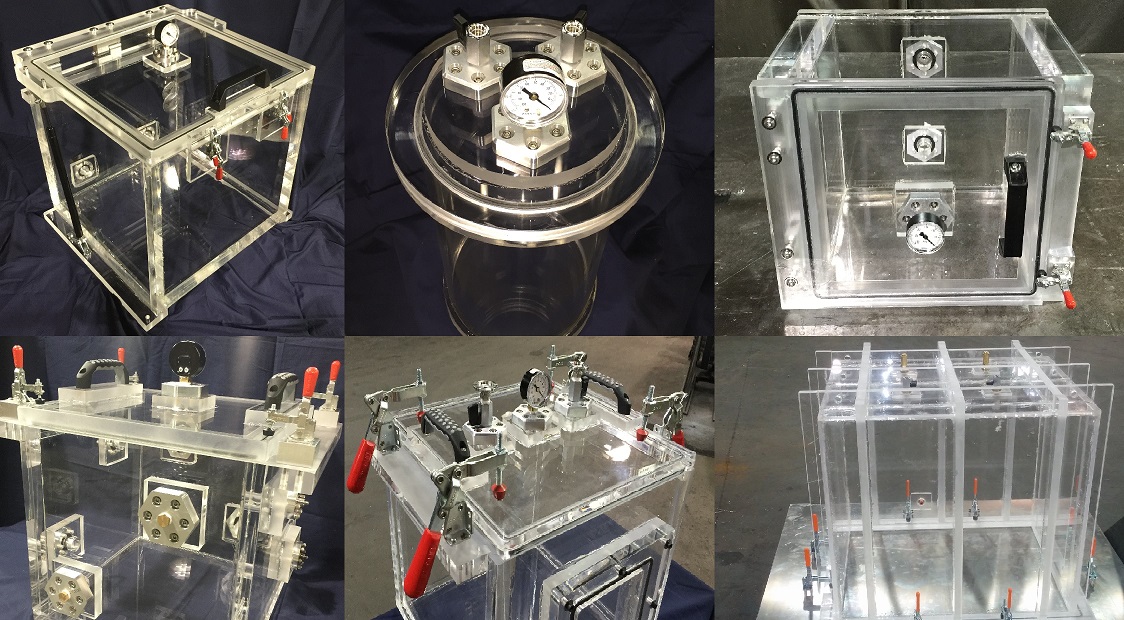

Vacuum Wobble Stick And A Vacuum Linear Actuator

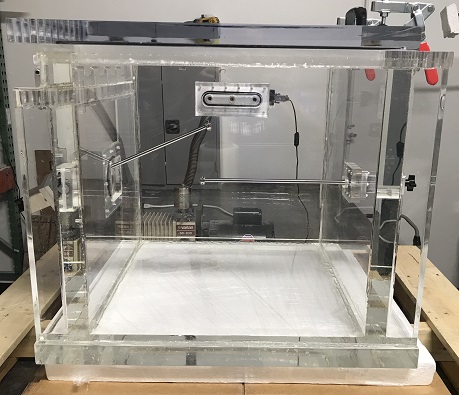

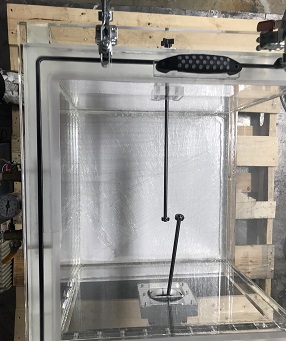

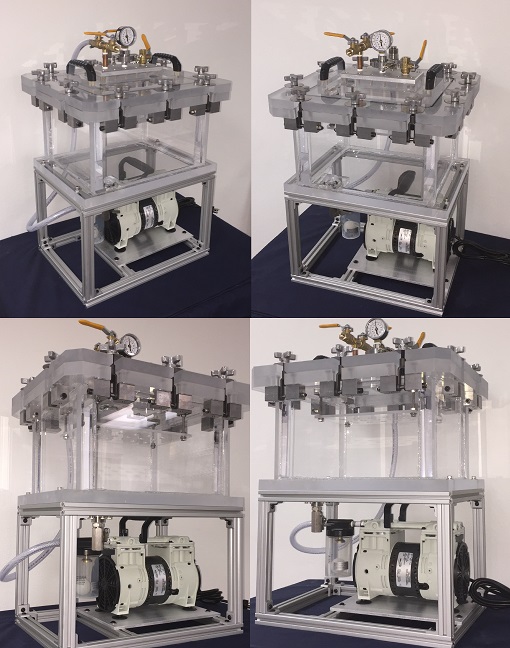

A Vacuum Wobble Stick And A Vacuum Linear Actuator are used to interact with chamber interiors while the chamber is closed and under vacuum. This is our standard 20 inch acrylic vacuum chamber, hinged front door that features two types of vacuum motion, manipulation, and interaction while specimen is under vacuum.

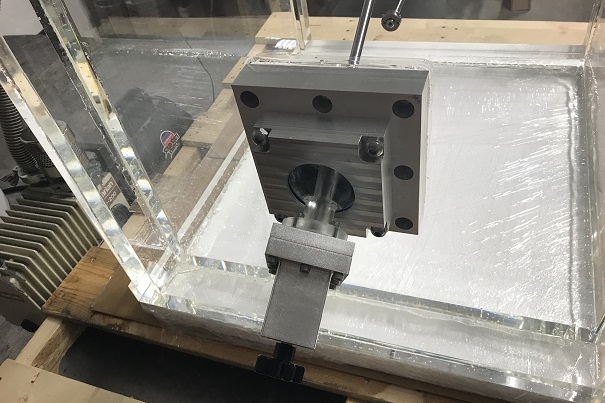

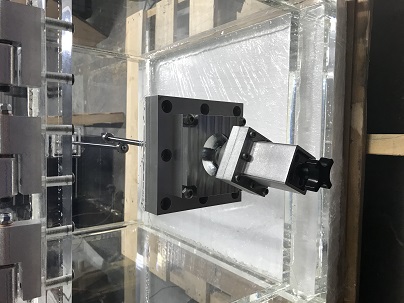

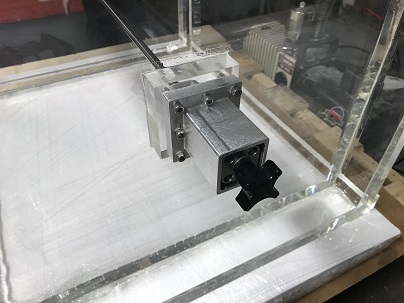

The first type is a vacuum wobble stick which is the only one in the vacuum industry to have the ability to wobble at 60 Degrees conical angle, have a linear travel of 10 inches, and have full clockwise and counterclockwise rotation. The second type is a linear slide, it features a linear motion of 14 inches. In addition to linear motion, this vacuum linear slide is also capable of full clockwise and counterclockwise rotation.

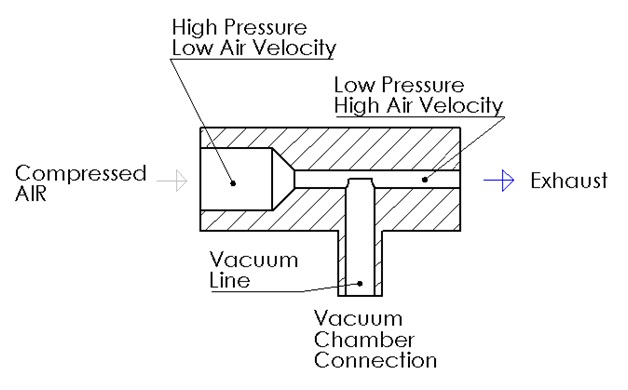

Keep in mind that these vacuum actuators are not rated for UHV, these are designed for rough, low, and medium (RLM) vacuum environments to be used specifically with acrylic vacuum chambers or in systems where UHV is not a requirement. The advantages of using such vacuum actuators in RLM environments is the cost savings that are an order of magnitude lower as well as the simplicity of design, customization, and integration.

Video of the Vacuum Wobble Stick And A Vacuum Linear Motion Actuator

You may be interested in some of our other items

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers