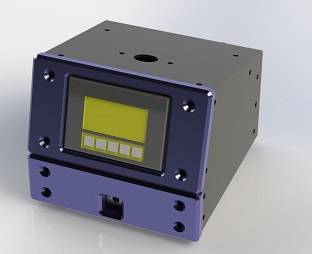

Vacuum Decay Leak Testing Systems

Vacuum Decay Leak Testing Systems are Instruments that detect and quantify a leak by measuring the drop in vacuum (pressure) inside the specimen. During a vacuum decay leak test, the specimen is placed into a vacuum chamber, the vacuum is pulled to a specified setpoint, and the drop in vacuum is monitored and recorded over time. If a leak in the specimen exists, the air will travel from a higher pressure (inside the specimen) to a lower pressure (vacuum chamber). As a results of the additional air, The absolute pressure inside the vacuum will increase which leads to a detection and quantification of a leak.

A vacuum decay leak test is both similar and different to a pressure decay test. They are similar in a way that both measure the change in pressure over time. They are different in a way that a vacuum decay measures a pressure increase over time whereas a pressure decay measures a pressure decrease over time. In a vacuum decay test, the specimen does not need to be connected to a pressure source this means that the specimen can be enclosed and fully sealed; one example are rigid containers, batteries, or pouches; all specimen are examples of not having the ability to connect to a pressure port. Another advantage of a vacuum decay test is that it has ten times higher sensitivity than a pressure decay test.

The aforementioned advantages come at a trade-off. The first trade-off is that since a vacuum decay specimen is not connected to an air supply (pressure source), there is only a limited amount of air which can leak out of the specimen. This can sometimes become an issue when an especially large gross leak is present. Another trade-off is that a maximum pressure differential of 15 psi is common. Since the specimen are sealed at ambient, sea-level conditions, the internal pressure is 15 psi absolute.

Common applications include but are not limited to quality testing of:

■ Catheters ■ Syringes ■ IV Bags ■ Biotech Valves ■ Test Pouches ■ Serum Tubes ■ Medical Pumps ■ Endotracheal Tubes ■ Nasal Tubes ■ Masks ■ Prosthetics ■ Fuel Pumps ■ Break Hose Testing ■ HVAC Systems ■ Bulletproof Vests ■ Food Trays ■ Heat Sealed Pouches ■ Fully Enclosed Containers ■ Water Proof Electronics ■ IP67 ■ Medical Equipment ■ Medical Seals

Quick Facts

10-4 sccm

NO

YES

ASTM F2338

NO - must be customized to specimen