In the article we are going to cover rotary vane vacuum pumps. We will touch upon how they work, what they are used for, when to utilize a rotary vane vacuum pump, its advantages and disadvantages.

Perhaps you have noticed that rotary vane vacuum pumps come in all shapes and sizes. On one website, the vacuum pump is less than $100; on another website, you see a vacuum pump quoted at $10,000. I would imagine that you immediately ask yourself what the deal here is.

Luckily, this article is here to help answer some of these questions. The goal of this write up is to help you fully understand rotary vane vacuum pumps.

By the end of the article you will understand the following:

1. What a Rotary Vane Pump is

2. How a Rotary Vane Pump Works

3. Why a Gas Ballast is necessary

4. Performance of a Rotary Vane vacuum Pump

5. Advantages and Disadvantages of Rotary Vane Vacuum Pumps

6. The quality difference between each vacuum pump and why some cost $100 and others $10,000

7. How to get the best vacuum pump at the best price

What is a Rotary Vane Vacuum Pump?

The Rotary Vane Vacuum Pump is an oil sealed vacuum pump, meaning that the evacuation chamber is filled with a specifically formulated mineral oil which acts as a sealant and lubricant between the vanes and vacuum pump chamber housing. Rotary Vane Vacuum Pumps come in either one-stage or two-stage. Typical volumetric flow rates are between 2 to 20 Cubic Feet per Minute (CFM). A Rotary Vane Vacuum Pump can generate a vacuum of about 1 milli Torr which is why they are preferred as a roughing pump for a plethora of vacuum applications.

How does a Rotary Vane Pump Work?

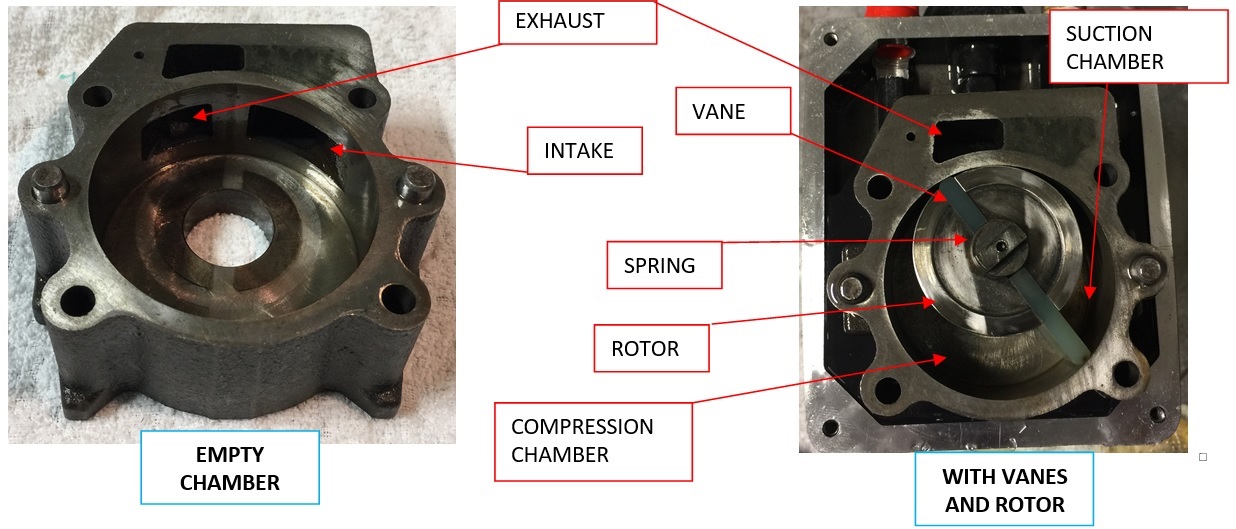

The Gas Enters the Suction Chamber and is immediately compressed by the vane of the rotor. As the rotor rotates, it pushes the gas molecules around the pump chamber and towards the exhaust where it is expelled to the atmosphere.

The Vanes are spring loaded which is how these create an air-tight seal between the rotor and the pump chamber housing. Conversely, these vanes and rotor housing are sealed by a specifically formulated, low vapor pressure, oil which acts as a sealant, lubricant, and coolant of the vacuum pump.

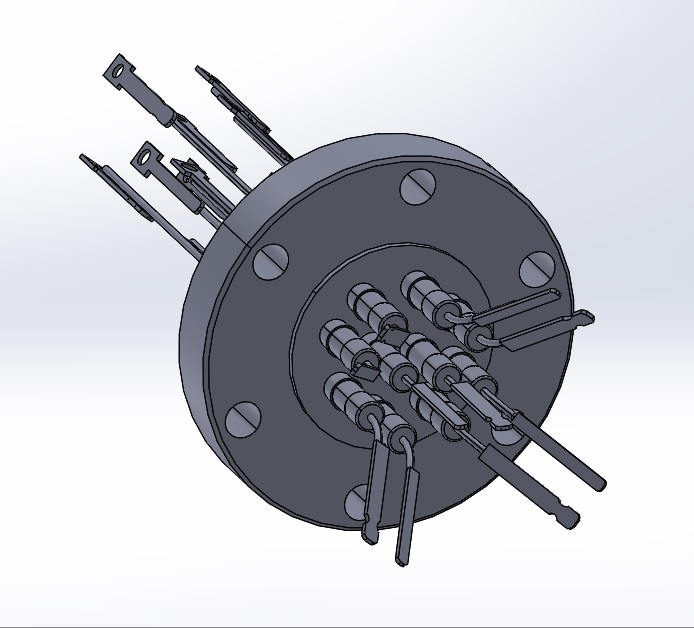

There are several types of drives that power the vacuum pump rotor. The first one is a direct drive, which is connected to the rotating power source, in most cases an electric motor, through a crankshaft and coupling. The second drive type is a Belt Drive pump which is connected to the rotating power source through a pulley and belt.

The Direct drive rotary vane pumps typically operate at roughly 1750 RPM and at a temperature of 70 Degrees Celsius. Pumps that use a speed reducing pulley, (Belt Drive) operate at a lower RPM. The operating temperature of belt driven pumps is 10 to 20 Degrees Celsius lower than the direct drive vacuum pumps. However, the operating temperature of each pump type is heavily depended on several factors such as the rotating speed, the viscosity of the vacuum pump oil, the quality of the oil, the age of the vacuum pump, the quality of the gas being pumped out, and the quality and type of the vacuum pump.

Rotary Vane Vacuum Pumps generally come in two types: Single-Stage or Two-Stage, sometimes referred to as Double-Stage. A second stage is created by connecting the intake of the second rotor to the exhaust of the first rotor. The advantages of a two-stage rotary vane pump are that a lower vacuum and a higher volumetric flow rate can be achieved this way.

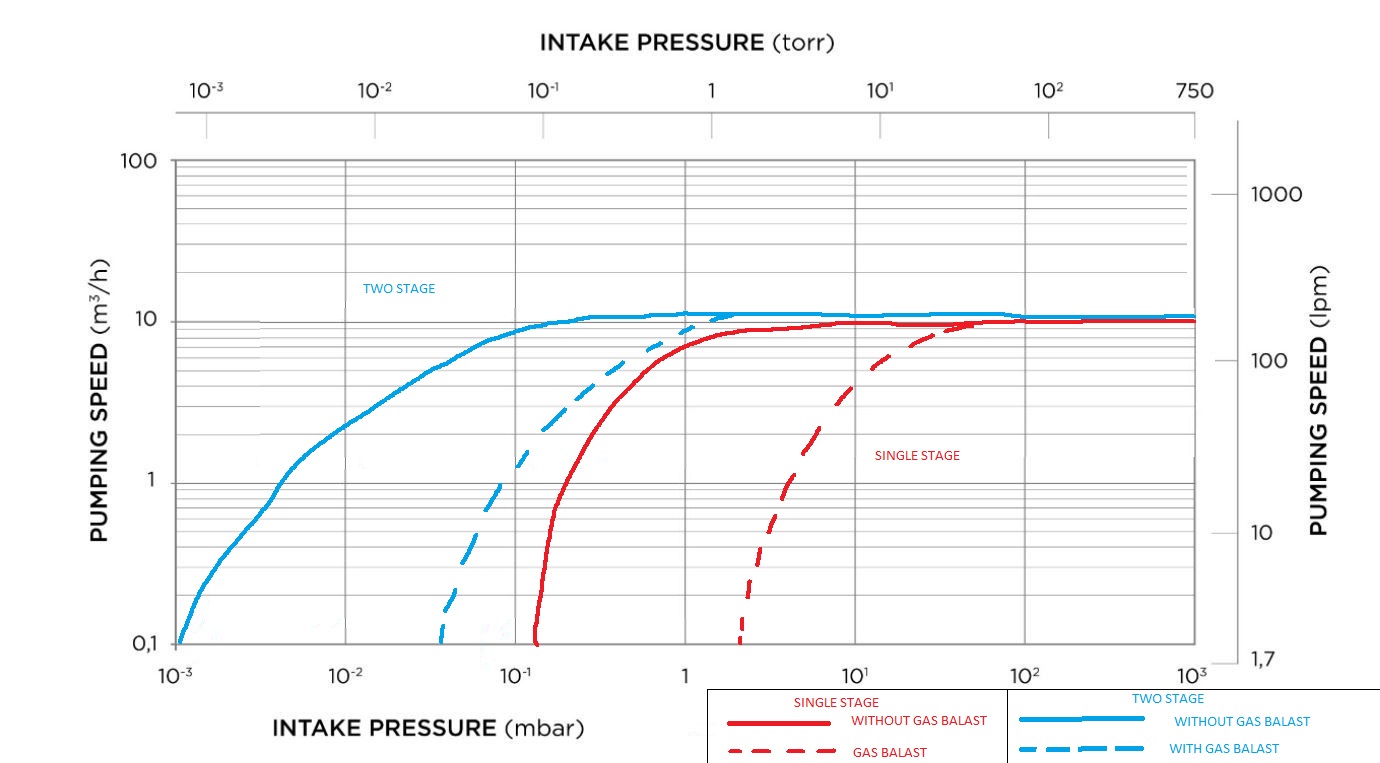

As with any other vacuum pump, the volumetric flow rate decreases as the vacuum inside the vacuum system or chamber increases. This is due to the fact that the less air is present inside the vacuum chamber, the harder it becomes to remove additional gas molecules out of the vacuum chamber or system. However, the pump performance of the two stage vacuum pump becomes much more evident as the absolute pressure decreases. The pumping speed is essentially the same in the rough vacuum range, but as the absolute pressure passes 1 Torr, the two-stage vacuum pump continues to keep its pumping speed, whereas the single-stage vacuum pump starts to decline.

Based on the graph, you can evidently see why single stage vacuum pumps would be beneficial over two-stage and vice versa. In rough vacuum environments, there is no difference between a single stage and a two-stage vacuum pump meaning that a single stage vacuum pump will provide the same performance at about 30% to 50% less cost. On the other hand, the performance of a single stage vacuum pump begins to decrease after 1 Torr and a two-stage vacuum pump becomes the obvious choice.

The graph below shows the pumping speeds of a single stage and a two-stage rotary vane pump with and without the gas ballast valve.

Single Stage and Two Stage Vacuum Pump Performance with and without Gas Balast

Why is a Gas Ballast Valve Necessary?

When the gas is pumped out of a vacuum system, the gas is not fully clean and will consists of contaminates such as water vapor, acetone, alcohols, solvents, and other condensable gasses. The aforementioned gasses will cause condensation to occur inside the vacuum chamber housing. This condensation happens before the gasses are exhausted. This then causes the vacuum pump fluid to be contaminated. As the vacuum pump oil becomes more and more contaminated, the vacuum pump performance will begin to decrease gradually, the ultimate pressure of the vacuum pump will decrease and deposits will start to form and build up inside the vacuum pump housing. Continual build up of these deposits will damage the vacuum pump components and seize up the vacuum pump making it inoperable.

This is where the gas ballast valve comes into place. It is used to let ambient air, or so-called ballast air, to enter the compression chamber. This air causes the discharge valve to open and discharge any condensable gas before it condenses and deposits onto the chamber components. In turn, the contaminants are exhausted out of the vacuum pump chamber before they have had the chance to condense. Opening the gas ballast valve will protect the vacuum pump but it will decrease the performance of the vacuum pump; therefore, there is a trade off.

Additionally, a gas ballast valve can be used as a diagnostics tool to help determine contaminated fluid from a leak. When the gas ballast valve is opened, the inlet pressure of the vacuum pump will drop. You can then close the gas ballast valve and watch the inlet pressure. If the inlet pressure slowly creeps upwards after you have closed the gas ballast valve, you have contaminated vacuum pump oil. This is due to the fact that the opened gas ballast valve was supposed to let any impurity out of the pump. After you have closed the valve, contaminates in the vacuum pump oil started to condensate and increase the inlet pressure. At this point, you should investigate further or change the vacuum pump oil in order to protect your vacuum pump and prevent further damage.

What is the Rotary Vane Vacuum Pump used for?

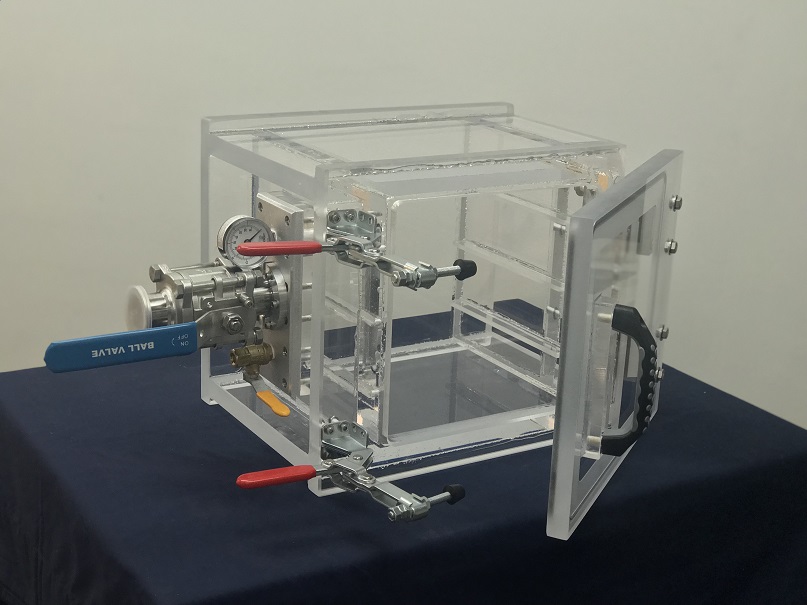

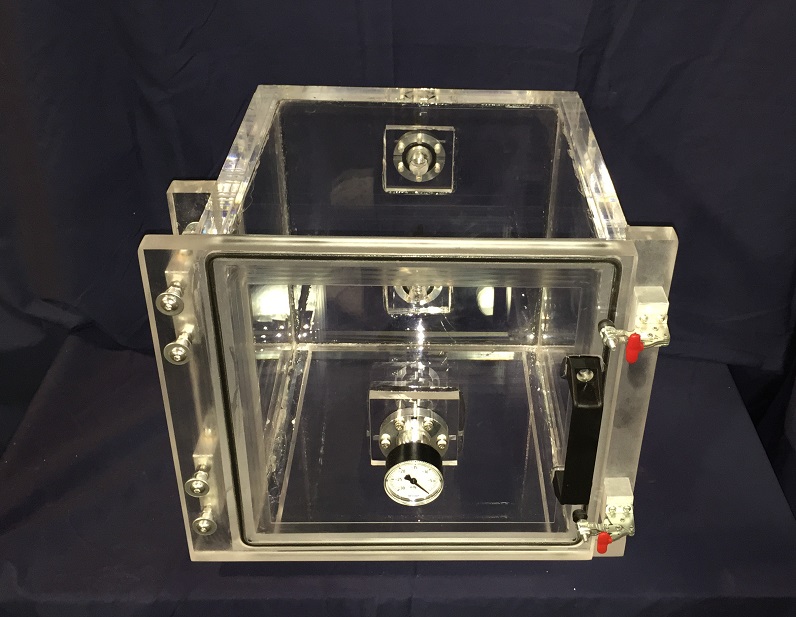

A Rotary vane Vacuum Pump is used to evacuate air (or gasses) out of a vacuum chamber or vacuum system throughout the Rough Vacuum Range. A “Rough Vacuum” is referred to as a system which as an absolute air pressure between 760 Torr (ambient) and about 1 Torr. There are many High Vacuum Pumps, such as Turbomolecular Vacuum Pump that cannot operate, and will get damaged, in the Rough Vacuum Range. Therefore, a Rotary Vane Pump is many times referred to as a Roughing Pump. A Roughing Pump is a Pump that is used to take the absolute pressure of a vacuum chamber or system from atmospheric pressures to 0.001 Torr or 1 micron. At this point, a secondary Vacuum Pump, such as a Turbo Pump will switch on and take over the pumpdown to take the vacuum chamber or system to higher vacuums such as 10-5 Torr.

The performance of a Rotary Vane Vacuum Pump

The performance measure of any vacuum pump is its ultimate pressure rating usually in Torr (micron), mBar, or Pascal (Pa) and its Pumping speed in CFM, Liters per minute, or cubic meters per hour. Make sure when you are shopping for rotary vane pumps that you compare unit to unit, apples to apples, and oranges to oranges.

The Rotary Vane Pump is a very popular vacuum pump for the following reasons:

Advantages of using Rotary Vane Vacuum Pumps

Practical and Versatile

A rotary vane pump is one of the few choices that is used as a roughing pump or as a primary vacuum pump to bring the absolute pressure down to a level where other vacuum pumps can be activated (such as a turbo pump).

Additionally, a rotary vane pump can also be connected to the exhaust of a roots vacuum pump in order to quadruple the pumping speed and volumetric flow rate. Keep in mind that a Roots Vacuum Pump cannot operate by itself and a rotary vane pump must be connected to its exhaust.

Good Vacuum Rating

A Decent Rotary Vane Pump can reach maximum vacuum levels of 1 micron which equal to one thousands of a Torr.

This vacuum rating is 99.999% vacuum and as you can see will cover the majority range of vacuum. This means that a rotary vane pump can be utilized in many vacuum applications, except in the Ultra High Vacuum Realm.

Good Air Flow

Rotary Vane Pumps are used in small and medium vacuum systems due to the fact that the average airflow they produce is in the range of 4 to 35 cubic meter per hour (2 to 20 CFM). Although, some pumps can produce higher airflows, up to 120 CFM, depending on setup. This makes them a good candidate for backing pumps for Turbomolecular Pumps or Diffusion Pumps.

Cost Effective

All things being equal, a rotary vane pump is a fairly inexpensive vacuum pump. A really good heavy duty vacuum pump can be purchased for around $2,000. At the same time, if you need to go cheap, you can go cheap and purchase one of those low quality, low duty vacuum pumps for as low as $80. Therefore, as you can see, you can save yourself lot of trouble because you have choices and variety when it comes to rotary vane pumps.

Robust

With proper care, a rotary vane vacuum pump can last you several years. Proper care means that you should change the oil frequently and not incorporate this vacuum pump into vacuum systems that are corrosive or damaging to the pump without incorporating the proper protective components such as a humidity filter or trap.

Disadvantages of Rotary Vane Pumps

Vacuum Pump Oil Contamination Risk

The first disadvantage is the presence of low vapor pressure oil. The rotary vane vacuum pump cannot operate without the oil meaning that the oil has to be constantly watched, refilled, and replaced. This also puts the vacuum pump at risk of getting contaminated with high vapor pressure gasses which in turn decrease the vacuum pump performance and damage its components.

One way to mitigate contaminants from entering the vacuum pump chamber is to install filters and traps before the vacuum pump intake. This minimizes the contamination of the vacuum pump oil.

Oil Mist Exhaust

Moreover, the rotary vane pump emits oil and water mist from its exhaust into the surroundings. After some time, a single rotary vane vacuum pump can smoke up a closed room to a point where it becomes a health hazard. This disqualifies rotary vane pumps from being used in clean rooms or close environments or indoor environments.

The oil mist emissions can be minimized by installing an oil mist eliminator or an exhaust filter onto the vacuum pump exhaust. This simple step can decrease the emissions by 99.95%.

On Rotary Vane Vacuum Pump Quality

Ok, let’s answer the basic questions on why there is a such a large price range between rotary vane vacuum pumps. The easiest way to answer this is to compare rotary vane vacuum pumps with cars; more specifically to a Yugo, a Toyota, and a Rolls Royce with their respective price ranges of $120, $1,200, and $12,000.

For the lack of more sophisticated language, a rotary vane Vacuum Pump purchased from Amazon for $120 is the equivalent to purchasing a Yugo Vehicle. Just as the Yugo vehicle will get you around town, a cheap rotary vane vacuum pump will pull a vacuum and get the job done. And just as a Yugo will be unreliable and cause you a lot of headache; a cheap rotary vane vacuum pump will do the same. It may even go out on you after a few months of use. But let’s be honest, you got a Yugo because your alternatives were not within the budget. And just with most items purchased on a low budget, a low budget rotary vane vacuum pump will give you the trouble that comes with a low budget item.

We had to mention this because in the event that you are in a situation where your non-technical middle manager looks up the specs of this low budget rotary vane vacuum pump on Amazon and claims that he is saving the company hundreds, even thousands of dollars, your response should be the following: “Yes, the specs are comparable to a heavy duty industrial vacuum pump; however, this is a light duty vacuum pump that cannot be operated continuously. Moreover, the intake port is a 3/8 inch or 1/2 inch NPT with a cross section that is more than 5 times smaller than the NW25 or NW40 that comes on all higher ends vacuum pumps. This smaller cross section will cause the pump to perform much worse. A low end 6 CFM vacuum pump will take twice as much as a medium end or high end vacuum pump to decrease the absolute pressure from 760 Torr to 1 Torr. The building materials of a low end vacuum pump are of low quality; meaning that you are taking a gamble on the pump and may very well end up with a lemon. Just look at the reviews on any website that sells low end vacuum pumps and notice how many of them claim that the pump did not work and that the vacuum pump did not achieve the vacuum rating it claimed it would achieve. Another advantage of the higher end vacuum pump is that it can be rebuilt and better maintained.”

It is highly advisable for you to go with a heavy duty, industrial rotary vane pump for your vacuum system applications. Concurrently, the higher end rotary vane vacuum pump is utilized in larger vacuum systems where a specific performance is required.

How do you get the best Rotary Vane Vacuum Pump for the best price?

Getting the best vacuum pump depends on your application and project requirements. If your vacuum system is a light or low use and you only require a rough vacuum of up to 1 Torr. By light use, we mean that you will use this vacuum pump sparingly maybe for say 10 min to 15 minutes over a course of one hour and use this pump for several times per day and several times per week, then you should hop over to amazon.com and get yourself a cheap rotary vane pump. I know that we talked some smack on them earlier in this write up, but cheap vacuum pumps have their place too.

If you are an engineer, looking to specify an industrial vacuum pump that will be used continuously on your vacuum system, then you should do some shopping around. The higher end industrial vacuum pumps are made by Pfeiffer Vacuum, Leybolt, Edwards, and Welch. Please keep in mind that you will have to contact them and give them your information in order to start the sales and quoting process.

The best way to do it is to go onto their websites and find your local vacuum pump rep. Contact the local rep and get a quote. You must do this for other vacuum pump supplier as well. Buying an industrial vacuum pump is similar to the process of buying a car. You can always negotiate and get up to 10% or 20% discount on the listing price. Sometimes the rep from a higher end vacuum pump will match the price quote of the lower end vacuum pump and you will end up with a better pump for the same price.

In the end, you will have to do some legwork in order to get the best pricing, but it is possible. We also offer rotary vane vacuum pump on our website, click here. Or if you are more confused than before you started reading this article, contact us and we will do everything we can to get you what you need.

Final Notes

If you have gotten this far and read the whole article, we would like to sincerely thank you for it. It has taken us some time to research, write, edit, and re-write it so that it is a good resource for you.

If there is something in this write up that you found confusing, if you caught spelling and grammatical errors that are bugging you, if you have any further questions on this article, feel free to CONTACT US and let us know. If you have any more questions, please ask. If this article helped you understand rotary vane vacuum pumps better, please write to us and let us know.

Further Reading

Did you know that we carry a many more products?

We make Robustly Designed and Quality Engineered Systems. Check out some of our other items we carry that you can combine/integrate with your systems or projects.