This article is intended to be the Definitive Resource when it comes to Piston Vacuum Pumps. We know a thing or two about vacuum pumps because we work with them every day. In this article we will specifically talk about Piston Vacuum Pumps – the WOB-L and the ROC-R to be exact. By the end of this write up, you will know:

1. How the Piston Vacuum Pump Works

2. What the WOB-L and ROC-R is

3. Advantages of using a Piston Vacuum Pump

4. Shortcomings of the Piston Vacuum Pump

5. Processes and Applications where the use of the Piston Vacuum Pump is Beneficial

How the Wobbling Piston (Rocking Piston) Pump Works

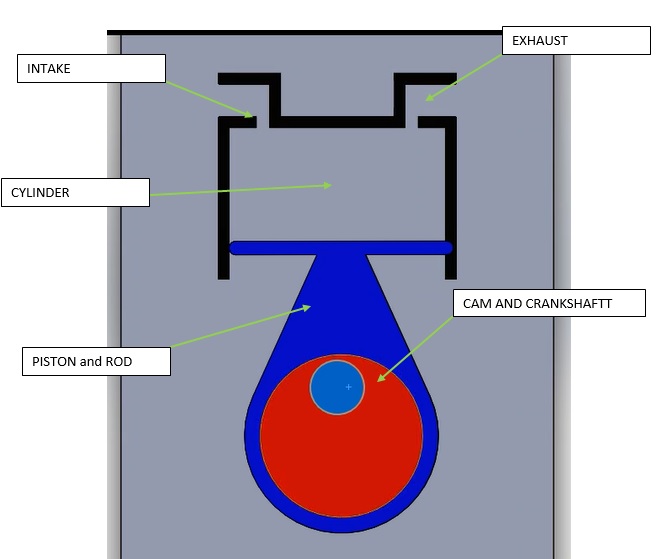

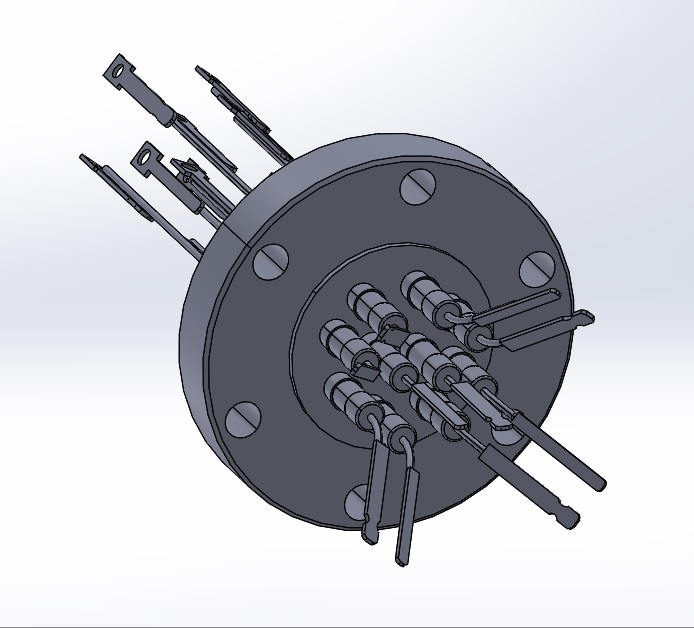

The principle of the wobbling piston (WOB-L) or rocking piston (ROC-R) is a very known and amazing concept utilized since the early days of the industrial revolution. The Wobbling piston is a simple design. The main components consist of a cylinder, a piston, and a crankshaft. This crankshaft is connected to a power source, which in majority of the cases, is an electric motor. The Piston is connected eccentrically to the crankshaft which converts rotation to liner motion. This enables the upwards and downwards movement of the piston.

However, unlike the more conventional cylinder-and-piston designs, the ones that we see in standard car engines, the wobbling piston does not have a wrist pin – this means that the piston rod and the piston are a single part. As a result, the piston does not move in a straight, concentric motion up and down the cylinder, but rather in a rocking motion. Due to this wobbling motion, the design does not permit the sealing to occur along the perimeter of the piston.

The Piston is sealed through a specifically designed Flanged Disk Cup. This Flanged Disk Cup is made from a certain polymer or polymer composite which is a trade secret of the vacuum pump manufacturer. The function of this flanged cup is to act as a guide for the piston and to create a seal between the piston and the inside of the cylinder hence enabling compression and suction. How well the wobbling Piston Vacuum or Pressure Pump will perform depends on the ingenuity of this flanged seal design. The Piston and the cylinder are made from lightweight die-cast aluminum that are treated for corrosion resistance from moisture – some cylinder designs feature highly durable polymers.

What is a WOB-L Vacuum Pump?

The Wob-L is a trademark patented by engineers at Thomas Company in 1960s who specifically designed the Wobbling Piston Pump for performance and reliability. Thomas Company is the daughter company of Gardner Denver and the Wob-L Vacuum Pump is made by Welch Vacuum; also a daughter company of Gardner Denver.

What is a Roc-R Vacuum Pump?

The Roc-R Vacuum Pump design is the answer from Gast Manufacturing to the Wob-L Design. The Roc-R is also a trademark that is patented by the engineers at GAST.

We would not be able to tell you the difference between the WOB-L and the ROC-R because the actual building blocks and parts are confidential. We are not really sure what WOB-L or ROC-R really mean – some say that these are nothing more than buzzwords, others swear that these are what makes these pumps unique. What we can tell you for sure is that both the Wob-L from Welch and the Roc-R from Gast are really good and reliable pumps and that our clients have been very happy with them.

How the Wobbling or Rocking Piston Pumps generate a pressure differential

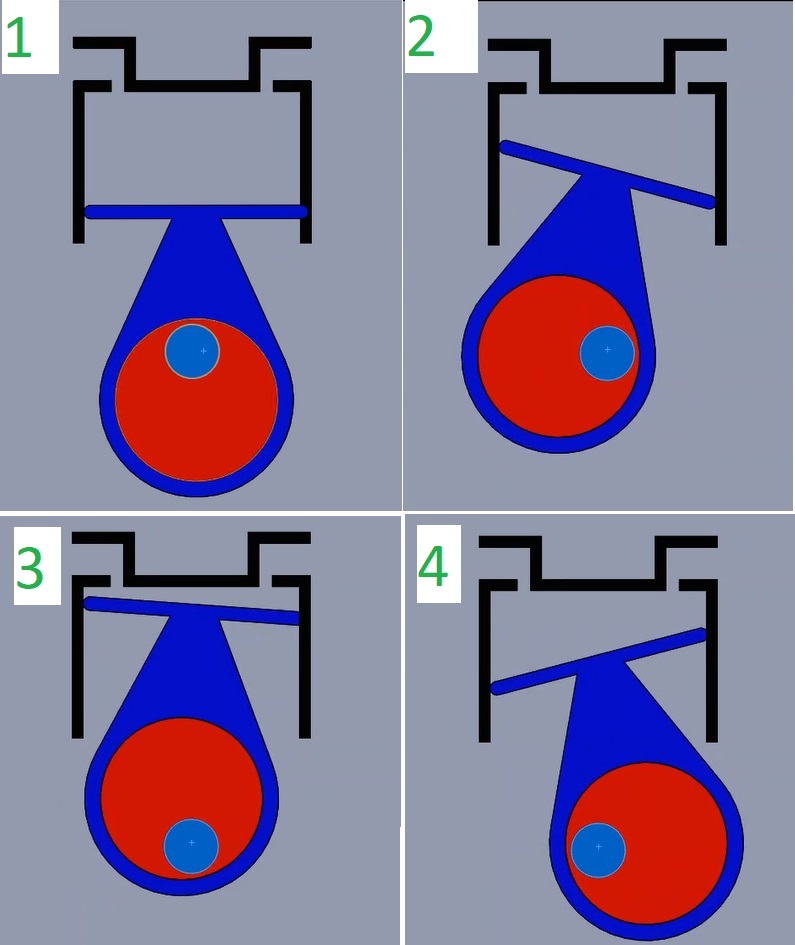

STEP 1: The air is evacuated through the motion of the piston inside the cylinder. As the piston moves downwards, the air is pulled into the cylinder - creating a vacuum at the inlet.

STEP 2: The piston then moves upwards compressing the air inside the cylinder and creating a pressure at the exhaust of the cylinder. This is how the air is moved out of a system – hence a vacuum is generated.

The inlet and outlet valves are sealed through so-called flapping valves that allow one directional airflow and will open and close based on whether there is compression or suction inside the cylinder.

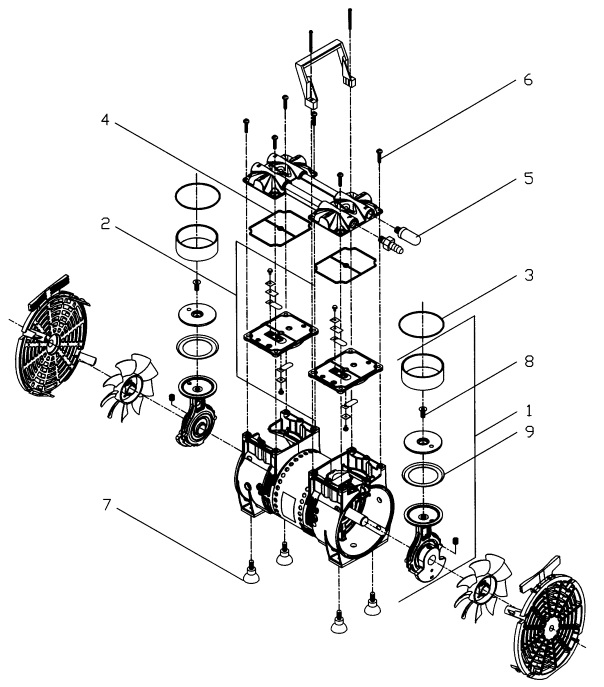

Multiple cylinders can be added to the system where the exhaust of the first cylinder is the inlet of the second cylinder. This two-cylinder system allows for better reliability and extends the useful life of the vacuum pump while enabling a deeper vacuum to be created.

One of the features of the piston pumps is the failure mode which is gradual rather than catastrophic. Keep in mind that depending on use and application, the internals will eventually wear. Fortunately, the wear is gradual meaning that the you will notice when the pump is going out by seeing an increase in ultimate vacuum the pump is able to pull and a decrease in flow rate. Fortunately, the WOB-L (ROC-R) Vacuum Pumps can be cheaply and easily rebuilt and the functionality fully restored by a qualified tech in 15 min to 1 hour if you have the rebuilt kit and parts.

Advantages of the WOB-L and ROC-R Pumps

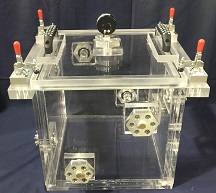

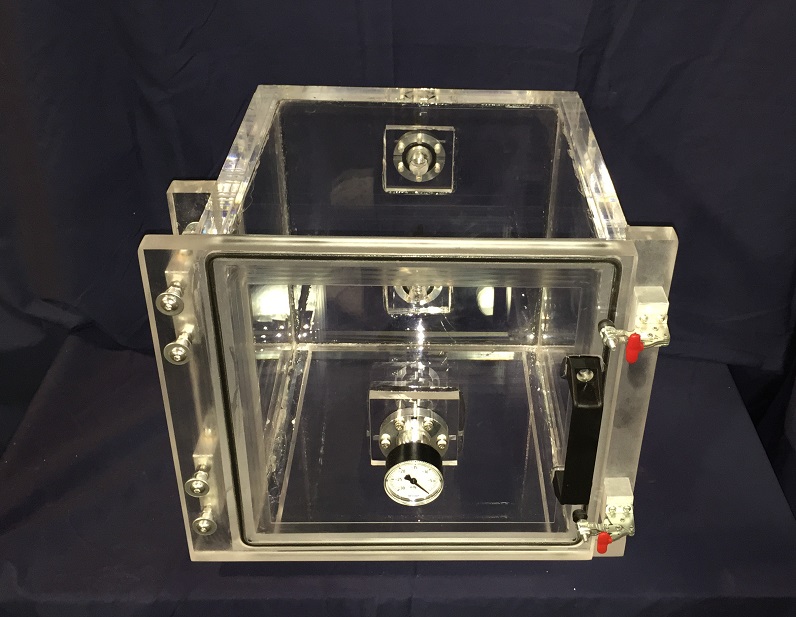

Compact Reciprocating Design

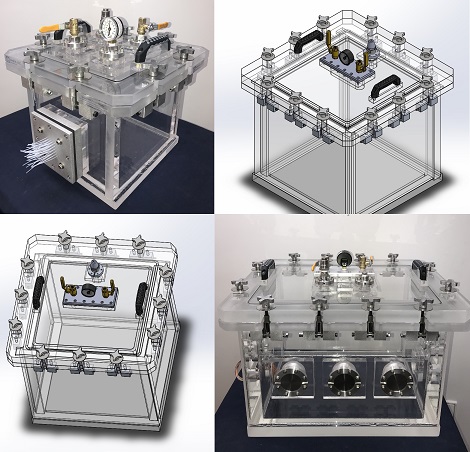

These pumps can act as a vacuum pump and as a compressor and therefore are very versatile to your applications. Conversely, the footprint of the vacuum pump is small and these pumps do not require too much power to be operated. Due to its compact design and clean operation, these pumps can be placed onto a counter top of a laboratory.

Oil Free Vacuum Pump

These vacuum and pressure pumps do not require a lubricant and hence there is no maintenance required. You do not have to check to make sure that the pump is lubricated. Another advantaged of this is that these pumps do not emit any pollutants into the surrounding environment. The Oil Free Pumps are very popular in clean rooms, laboratories, and closed rooms that have to be oil and mist free.

Lightweight and Reliable

The parts are made from either lightweight die-cast aluminum or high wear resistant plastic. This enables the pump to be operated reliably. The piston seal is made from a specifically formulated polymer or composite that offers long-life and high performance. The bearings are permanently lubricated.

Single or Multi Stage

Enabling a really good rough vacuum rating of up to 5 Torr which is pretty good for oil free piston pump.

Low Vibration

Components of these pumps are well balanced resulting is a low vibration.

Corrosion Resistant

All parts are treated to protect against corrosion. This means that an oil free pump will be able to handle high levels of air moisture and will not contaminate the vacuum pump as opposed to its lubricated counterparts. In addition to moisture, other contaminants can be removed with this pump. Please note that the WOB-L and ROC-R are not recommended for pumping organic, acidic or basic vapors.

Disadvantages of the WOB-L and ROC-R Pumps

Rough Vacuum Only

The Oil Free Piston Pump is not intended for high vacuum applications as many vacuum pumps are rated between 5 and 219 Torr ultimate pressure. This covers a plethora of applications but does exclude this pump from the higher vacuum realm.

Flow Rates

Flow rates between 0.5 to 7.1 CFM (200 l/min) are very reasonable but not the highest flow rates available. Most WOB-L Pumps operated in the 3 to 4 CFM range. This flow rate excludes these pumps from being used practically in large vacuum chamber systems.

Medium Duty Vacuum Pump

Meaning that this pump is not intended to be operated continuously.

Recommended Applications for the Oil Free Piston Pumps

1. Rough Vacuum Ovens used for drying, curing, bake outs, heat treating, aging tests, and vacuum potting where the vacuum level requirements are not deeper than 5 Torr.

2. Packaging and Food Industries such as Bubble Leak testing, Vacuum Packaging, Vacuum Package Testing, altitude Testing, and most ASTM package tests

3. Indoor facilities and Laboratories where exhaust contamination poses a risk or where exhaust absence is critical. These pumps are well suited for any commercial, academic, or research lab because the user will not be breathing in oil mist emitting from the pump. Any clean laboratory is recommended to use this pump.

4. Any process where the specimen or samples cannot be contaminated by outside fluids, lubricants, coolants, and other contaminants.

5. Medium Duty, Low maintenance environments where a reliable vacuum pump is needed and the need to maintain and service the vacuum pump is not main goal. This is an easily employed vacuum pump that can be operated by anyone with little or no training.

Dry Piston Pumps are NOT Recommended for

1. Freeze-Drying (Lyophilization) due to the fact that this pump will not be able to reach the required vacuum levels needed to successfully perform the proper freeze-drying recipe. We recommend a rotary vane pump.

2. Any process or technique used for pumping organic, acidic or basic vapors as these may interact with the internal components of the vacuum pump.

3. Any continuous duty process where the vacuum pump is going to be on all the time. The piston vacuum pumps are intended to be operated at medium duty which means that in a 1 hour period, these should be on between 15 to 30 minutes if these are to last you for many years.

WAIT! Take a look at similar Items you may like…

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.