If you are a food manufacturer, it is important for you to properly seal your product prior to shipment to customer. There are several reasons why you must have a good integrity of seal when sealing your food products. The first and foremost is the safety of your end user. The second is the safety of your business and bottom line.

This customer came to us because “The end user was receiving packages containing ants in it” They had sprayed their plant several times but the complaints kept coming. They contacted us because we not only supply packaging advice and package testing systems, but also because we are the experts when it comes to food package safety. As serendipity has it, at the time of their call, we had one of our design engineers visiting another client of ours who happened to be in the same city. We sent him to take a look at their plants and to look for ants.

Well, not a single ant was found, there were no ants in any of their plants. But what was founds were countless of terrible heat seals. Many of their packages were big leakers. This company was sending thousands of products to their customers each day! Something had to be done.

A quick examination of their Packaging Process revealed that they did not have an in line heat seal integrity testing process. What we suggested to them was to implement a long term solution of finding the root cause our their heat seal failures by examining their prepared food product lifecycles from “Pack to Snack”. The immediate solution was to get a heat seal integrity tester fast! We provided several options and they chose our bubble emission leak tester.

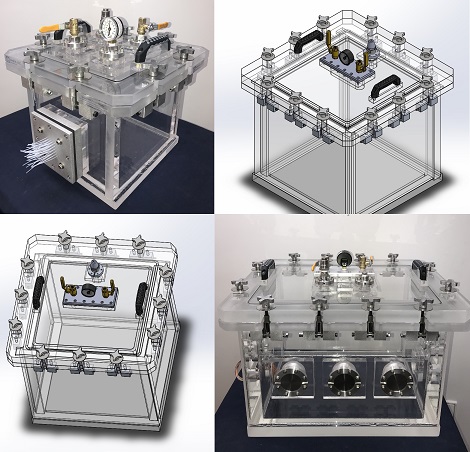

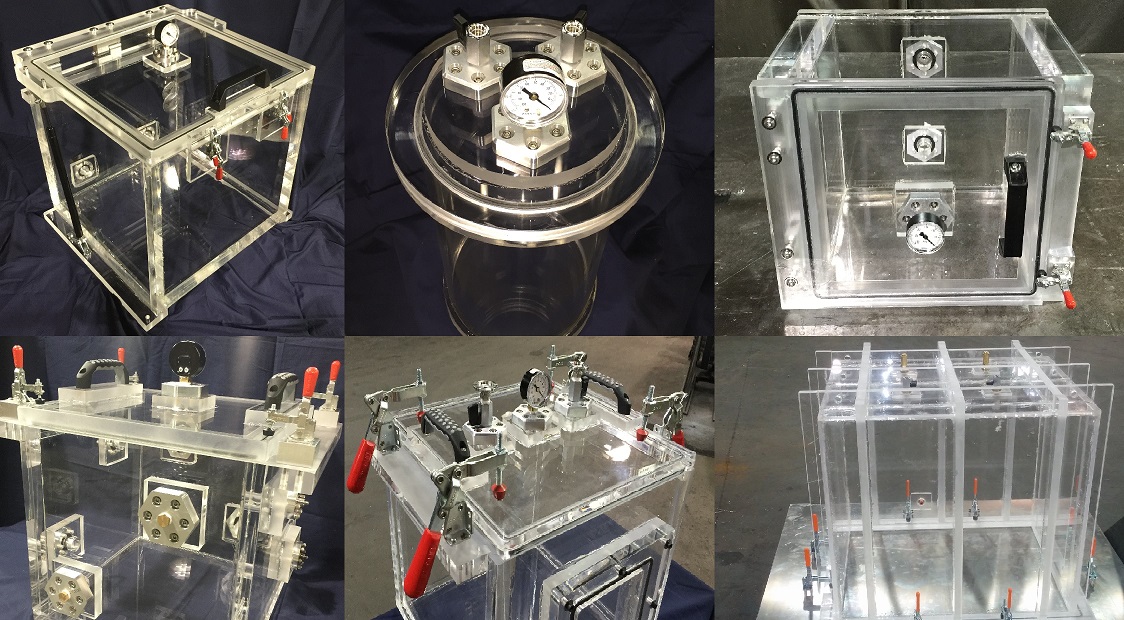

Our bubble emission leak tester was the best choice. We offer several options, we have the table top version, the adjustable feet version, and the lockable swivel casters version; which is what our client chose. This particular model is a top load, hinged spring supported lid bubble leak tester. It is 18 inches wide, 12 inches deep, and 10 inches high. On the lid, there is an adjustable package restraining mesh which will keep all inflated packages during bubble vacuum leak testing submersed under water. The Vacuum pump is a rotary vane vacuum pump, hooked up just before the intake is a water protection valve. This valve closes the vacuum hose if water is being pulled into the vacuum line. This can happen if the tank is overfilled with test specimen. Below the tank is a drain valve that allows for easy draining and cleaning of tank. This particular model is on lockable swivel casters which enables the operators to move this bubble emission leak tester across their plant.

A few days after we delivered this leak testing unit to them, they gave us a call. Initially we thought that something went wrong, but that was not the case. They asked us to help them improve the package seal integrity of their manufacturing product lines. They were serious about quality and about serving their customers. Their story moved us and we agreed on consulting them on their packaging operations.

In hindsight, we were the obvious choice to consult them because at the time of writing this, we have worked across 317 different industries; not companies, but industries. We have seen how other companies and industries perform package integrity testing. In addition to our broad industry experience, we also manufacture leak testing systems as well. Our expertise on heat seal quality is unmatched.

In no time at all we got to work to help them improve. We conducted a thorough audit of their machinery, processes, and quality control. By the time we were finished, our client went from several quality complains per day to zero complains in the past 2 months!

But where did the ants come from you may wonder? Well, we traced this one down as well. The packaged product was sent to a warehouse which would distribute the products to the local stores. Since the packages had compromised seals, the ants would enter the package and snack. In short, the ants entered the package at the warehouse – the warehouse in another state where the ants come from.

Are you a food packager? Contact Us now to find out how you can serve your customers better.

WAIT! Take a look at similar Items you may like…

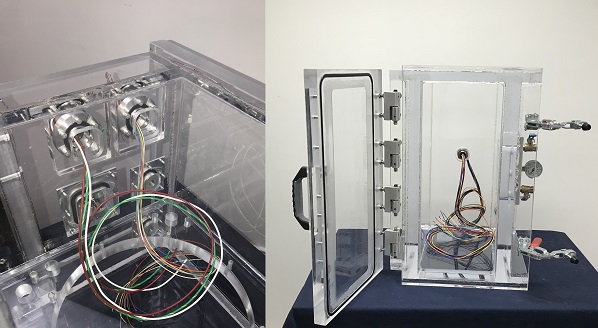

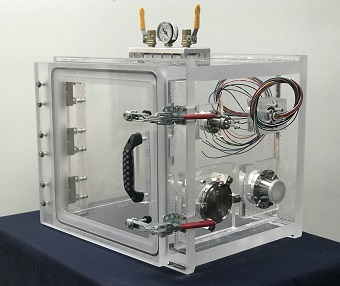

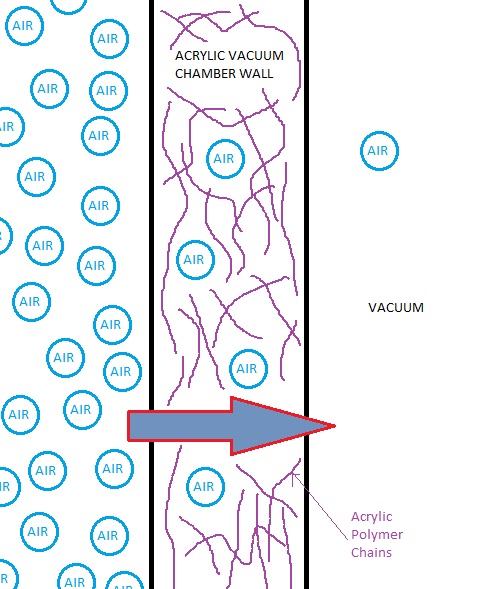

We make Robustly Designed and Quality Engineered Systems. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers