Electro-Optical Imaging Products have slowly become an irreplaceable part of our everyday lives. The simplest electro optical imaging product is the camera hardware and optics in our smart phones. The word “simplest” is actually used as a relative term here because our smart phone cameras are amazing technology. There are more sophisticated Electro-Optical systems which are build through the utilization of nanocrystals / nanomaterials to be deployed as a detection tool as a defense against chemical and biological threats.

Sophisticated Electro-Optical Systems have the ability to detect, track, and quantify a certain search criterion through spectral analysis of specific signatures. This is a very fascinating field of study.

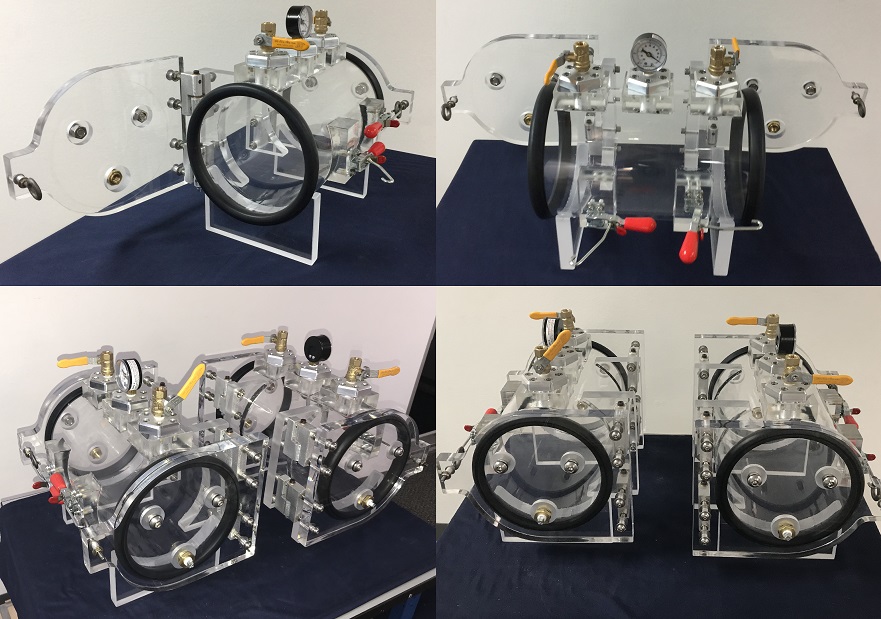

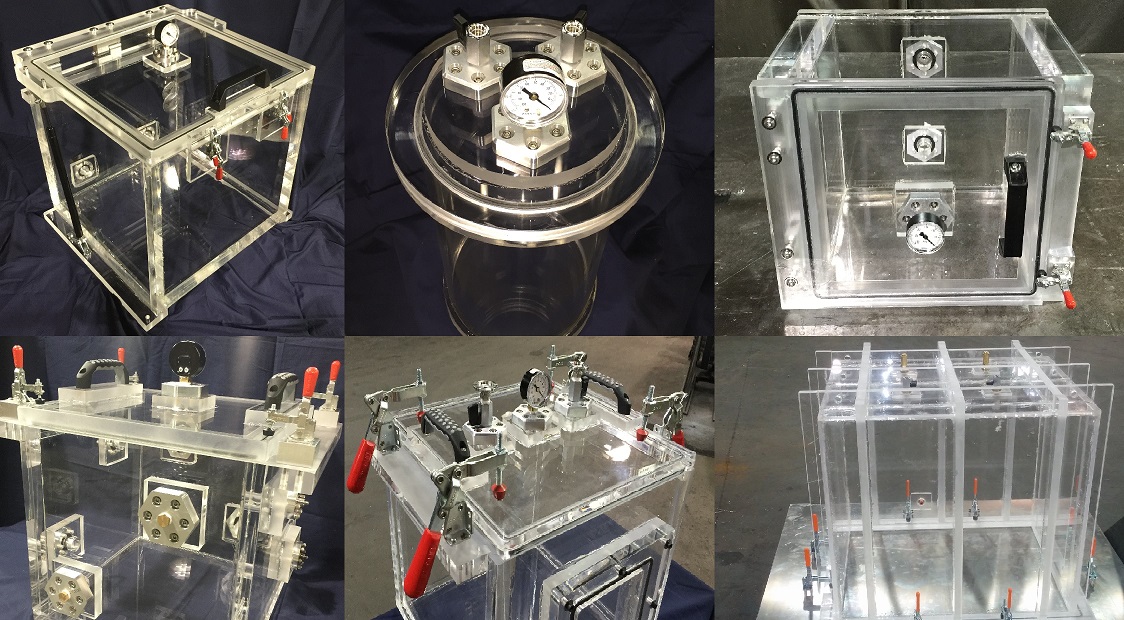

Our client came to us because they had a need for a custom-made acrylic vacuum chamber. The vacuum chamber had to be cylindrical, placed horizontally on a table top. For Easy Access, both the left and the right side of the cylinder had to be accessible; they wanted two doors to be hinged and swinging out. On the doors, they needed a liquid feedthrough, we provided them with a 1/4 inch NPT feedthrough that is threaded on the inside and outside. This will enable them the connect a tube and run their gas or liquid from inside towards outside without compromising the vacuum inside the chamber during operations. Finally, they required two additional power feedthroughs to be present on each door.

The power feedthroughs were proprietary and provided by our client – for testing purposes we used button head screws with an O-Ring on the outside to seal off the feedthrough port hole. The doors are latched with a Destaco Style Latch. You can see that we started to run out of space, but we managed to place all components onto this chamber. “What’s that you say? You want a total of two chambers? Sure, well be happy to build as many as you need”

Are you developing sophisticated and important products that require vacuum technology? If you are, Contact Us to find out how we can help you.

Some of our Popular Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers