Blister Packs are a type of Preformed Plastic packaging mainly used in the pharmaceutical industry. For packaging pills or medication. We have also seen blister packs used in the medical device industry (for packing surgical tools or bio-implants) and electronics industry (packaging of microchips).

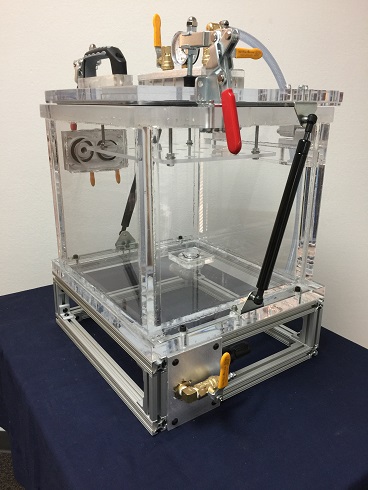

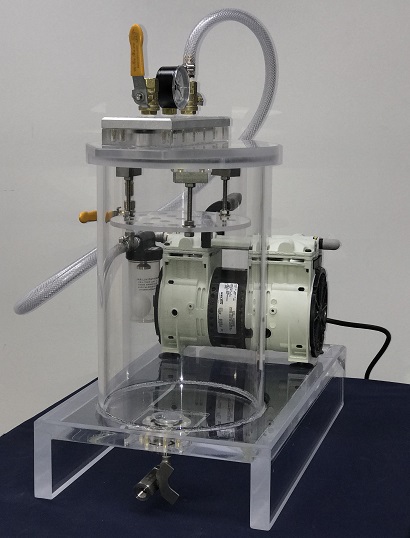

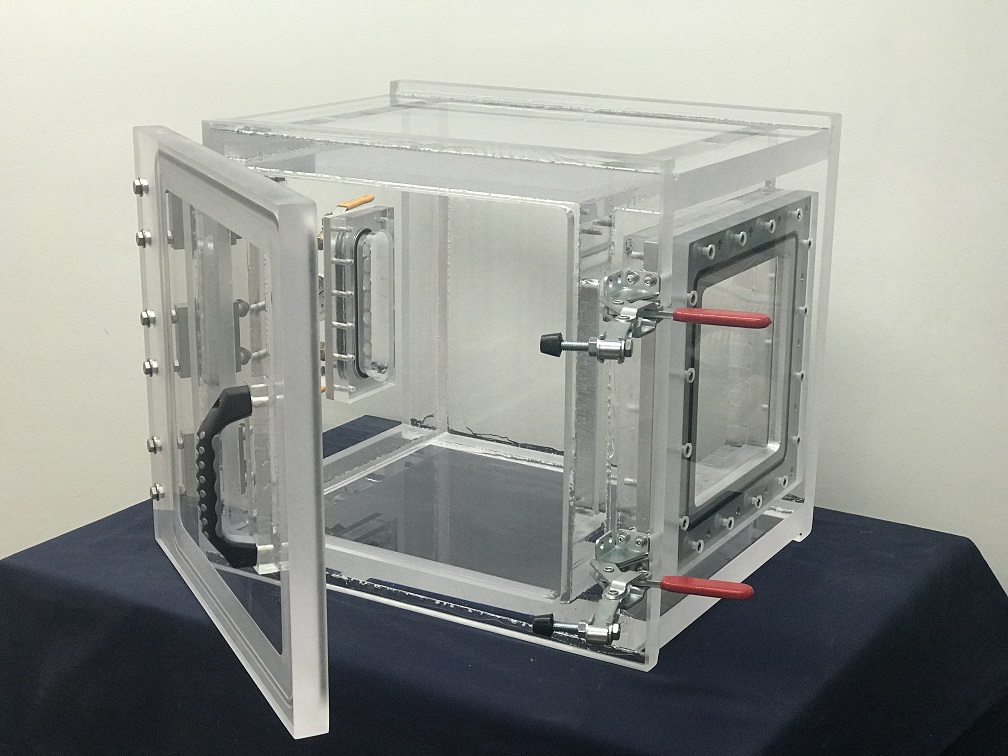

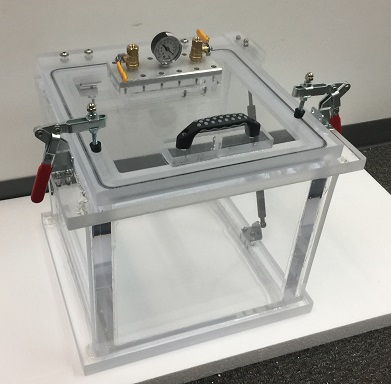

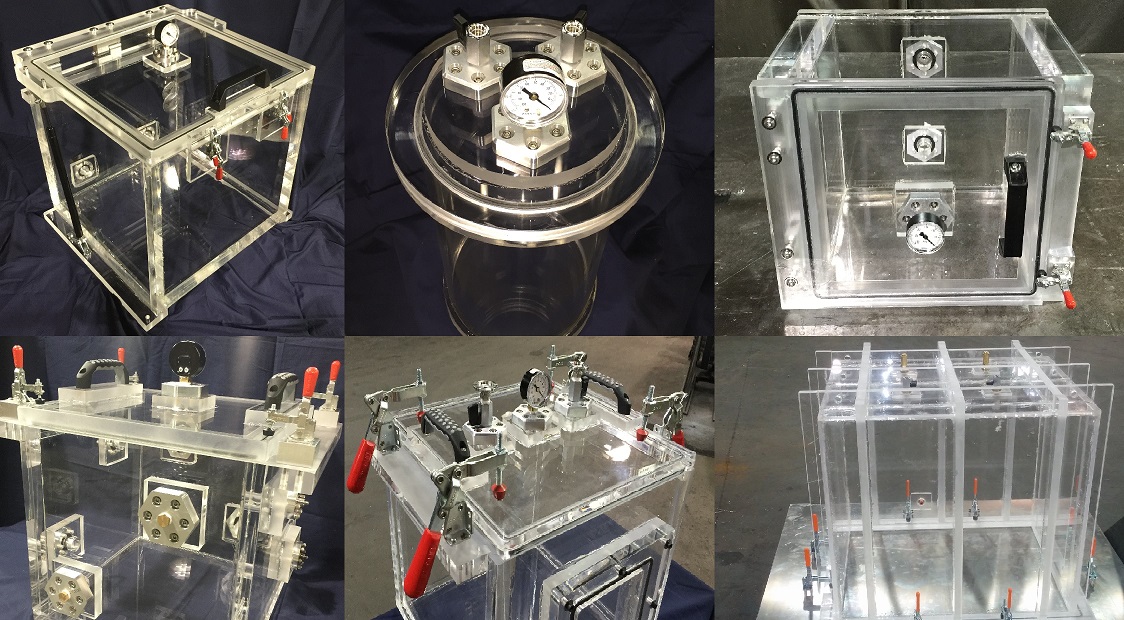

If you require to quality leak test your blister pack heat seals for proper seal, Bubble Leak Emission Tester is the simplest way to accomplish that. You are looking at our standard Bubble Emission Test System. This one is 12 inch Wide, 12 inch Deep, by 12 inch High. The vacuum pump is a venturi vacuum pump that uses compressed air to generate vacuum and evacuate the clear acrylic vacuum tank. The venturi pump can be actuated simply by toggling the air valve and letting the air flow into the venturi pump.

There are several advantages to using a venturi Vacuum Pump in a Bubble Leak Testing Application. One, there is no electricity required. Two, A venturi pump does not require oil or maintenance. Three, this system can be used on any table top with an air hook up. The cost is that a venturi vacuum pump is not as powerful and will not pull as much air out and go to as high of a vacuum – we are talking about 3.5 CFM at 26 inHg. This rating is enough for every bubble leak test out there.

If you are a pharmaceutical manufacturer looking to quality test your blister packs, contact us to find out how you can improve the quality of your production line.

Similar Items

We are an Engineering Excellence Company. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers