Have you ever had the need to run your electronics inside a vacuum environment? If the answer is yes, you have come to the right place.

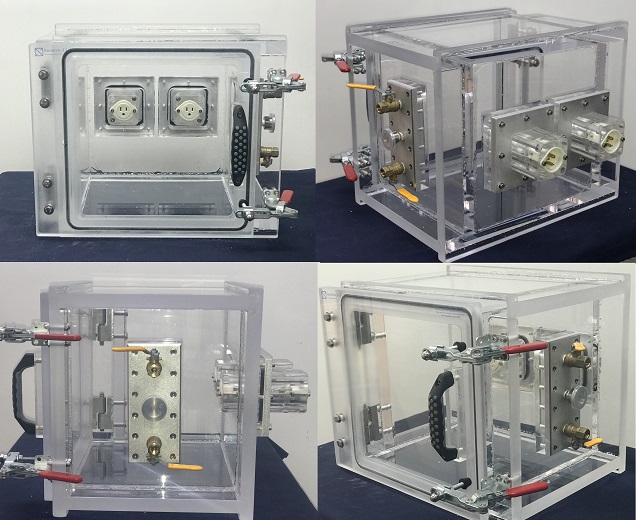

Our client had the need to power several electronic items and instruments inside a vacuum environment and had a need to plug the instrumentation into a electrical wall socket and then test these while pulling a vacuum. Conversely, our client planned on performing additional liquid and gas phase experimentation which is why they needed two electrical plugs.

We built an Acrylic Vacuum Chamber with two electrical plugs on the rear wall. All our client had to do is get an extension cable from their local hardware store and plug these in from the back of the chamber. Now, they can plug in their instrumentation from the inside of the chamber, close the door, and pull a vacuum.

This is a customization to our standard acrylic vacuum chamber, front loading door, with a hinged side door. The front loading door is beneficial when the vacuum chamber is placed onto a table top. The operator can simply load and unload the chamber sitting down at their desk. Finally, instead of a dial vacuum gauge, we supplied them with a NW25 fitting for them to connect a digital vacuum gauge capable of reading vacuum in 3 significant figures.

If you are a Biotech company looking for a robust and well-designed vacuum systems, Contact Us to find out why we are the market leader in our field.

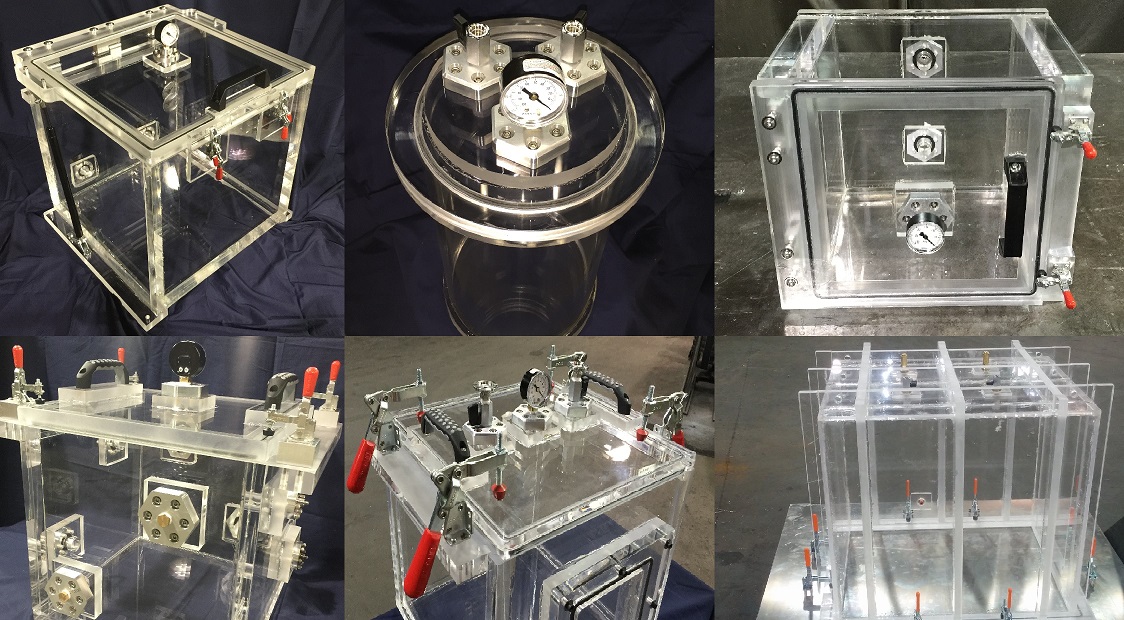

Did you know that we carry a many more products?

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers