Testing High Voltage Circuit Boards 350V at a Simulated Altitude of 60000 Feet

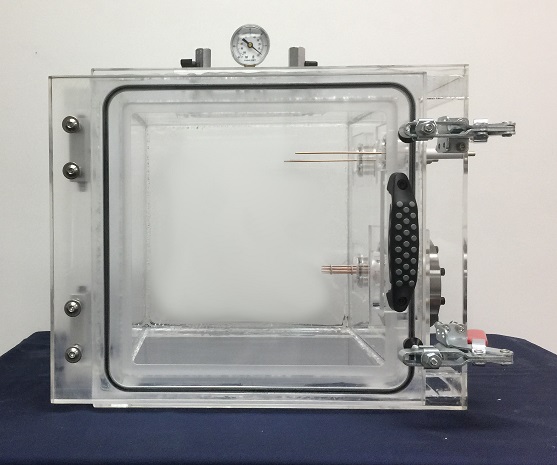

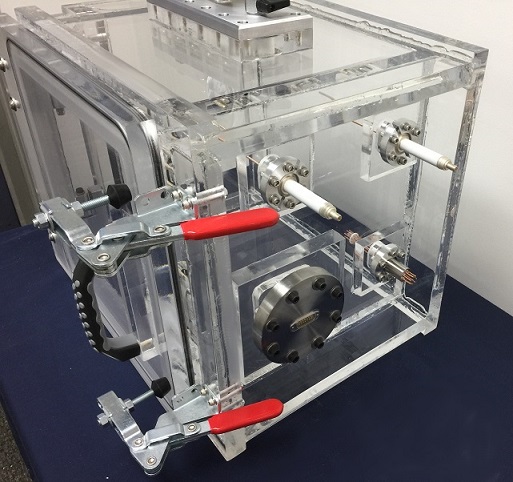

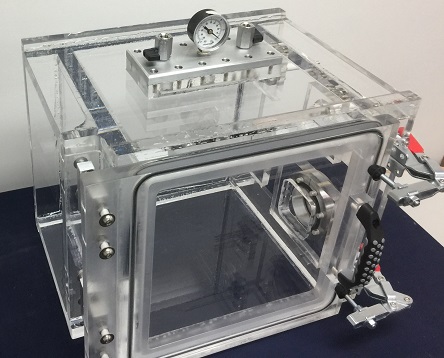

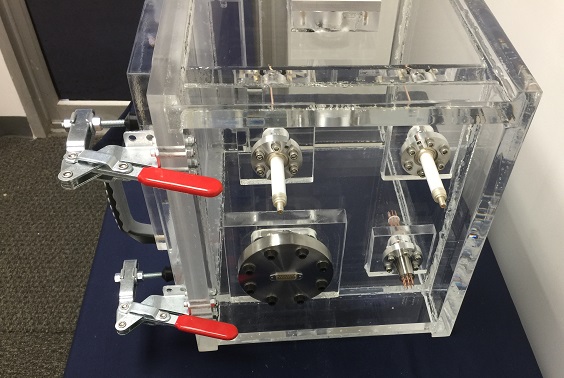

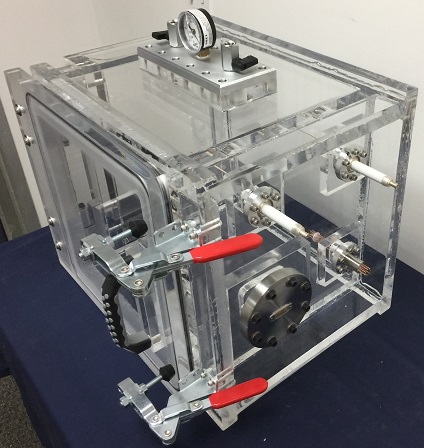

What you are seeing here is our crystal clear acrylic vacuum chamber, hinged side door with clamps. In addition, our client has asked us to add 1. A quantity of two high power feedthroughs on the top right wall, 2. An 8-pin power connector, and 3. a multi-pin feed through. These vacuum feedthroughs enable the routing of electrical power and signals from the outside of the chamber into the inside of the chamber without disrupting the vacuum.

The Feedthroughs are fully fastened to the wall and hermetically sealed by an O-Ring or Vacuum epoxy. The advantage is that the electronics can be connected and a vacuum can be pulled without leakage.

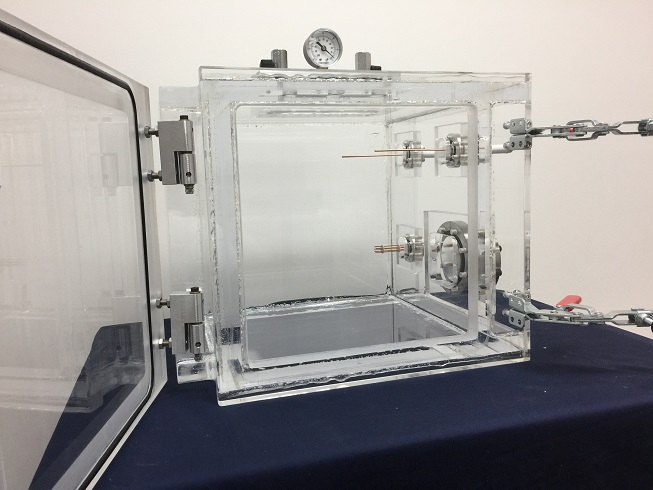

If we open the door, we can see the power cables perturbing into the inside of the chamber. Here, our client is able to connect these wires to their electrical device, close the door, and pull a vacuum. Because the walls are made of cast transparent acrylic, the electrical components inside the chamber fully visible during the test.

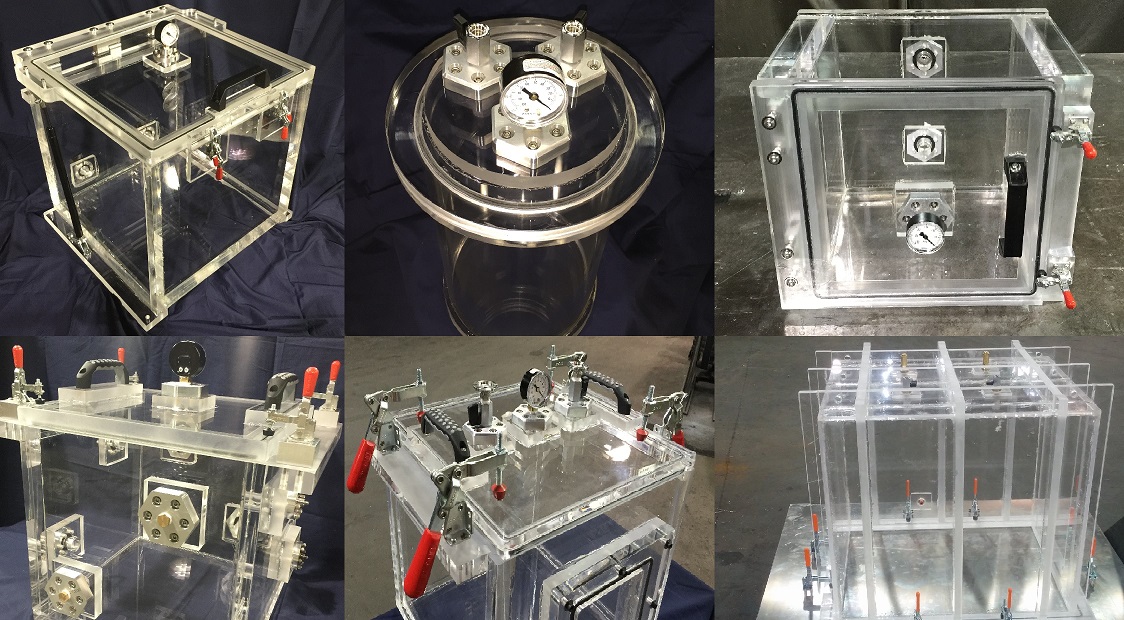

Some of our Popular Items

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers