Testing of High Potential Voltage Cable Discharge Arc Using a Cylindrical Vacuum Chamber

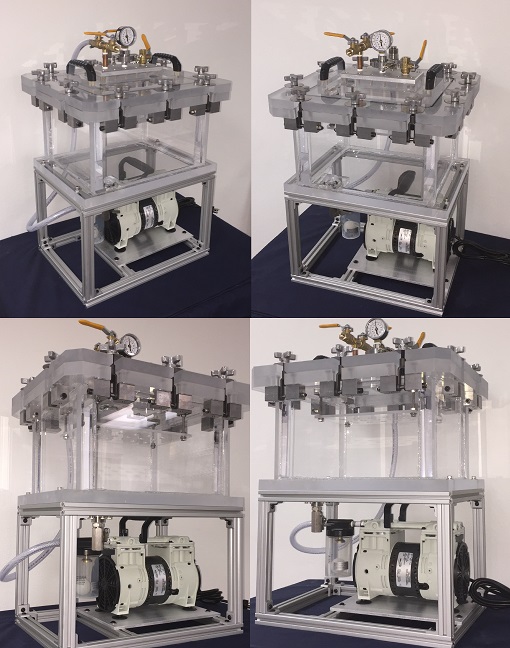

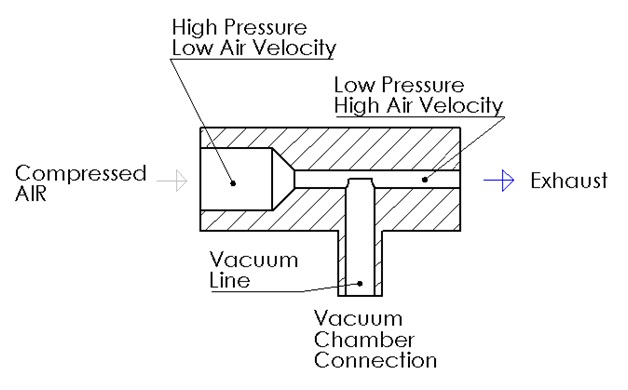

This cylindrical vacuum chamber is utilized for testing high potential voltage cables for potential discharging at higher altitudes. Since air is acting as an insulator at sea level, no electric discharge is present at lower altitudes. However, once the pressure is decreased as a result of higher altitudes, less air is present to act as an insulator. This creates a problem because if an electric discharge happens, it can result in catastrophic failure of electrical components, especially if these components are critical. It is therefore very important to test these cables for discharge by using a vacuum chamber to simulate an air pressure at higher altitudes. The vacuum requirements for this test where only to go to 35,000 feet pressure equivalent which is about 165 Torr.

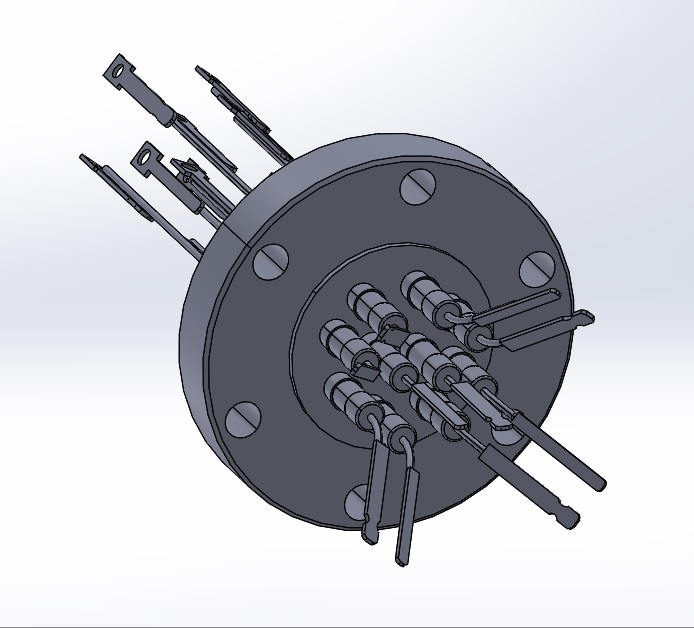

Our client provided us with a the test cable, which is a high voltage cable. The requirements were to test only one section of the cable. The challenge here is due to the fact that the test cable has various diameters and therefore a sealing plate must be designed to accommodate the proper thickness at which the cable is to be tested.

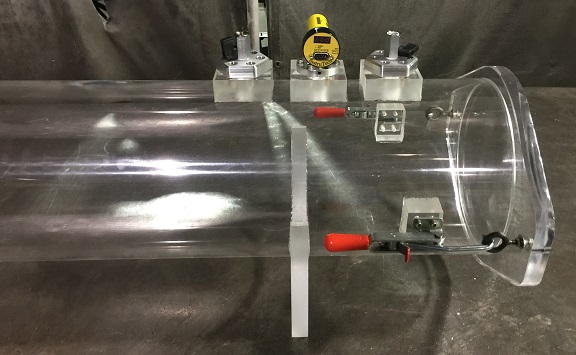

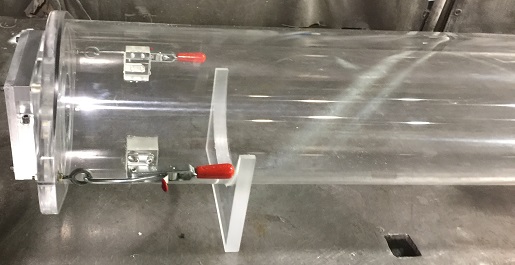

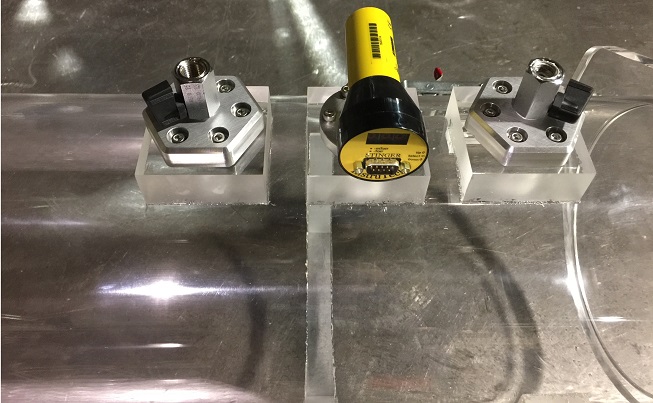

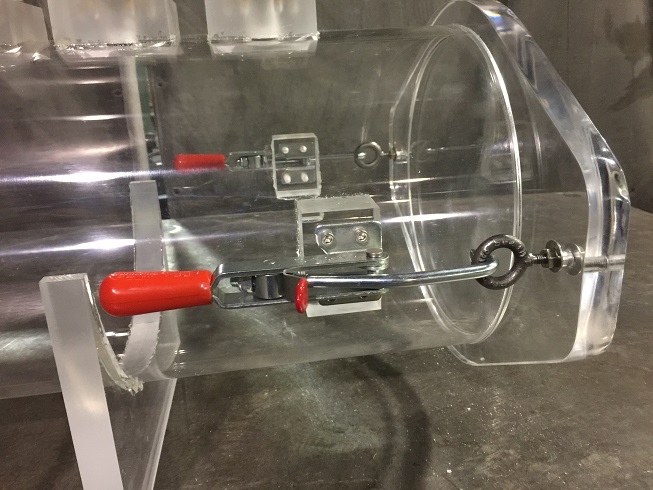

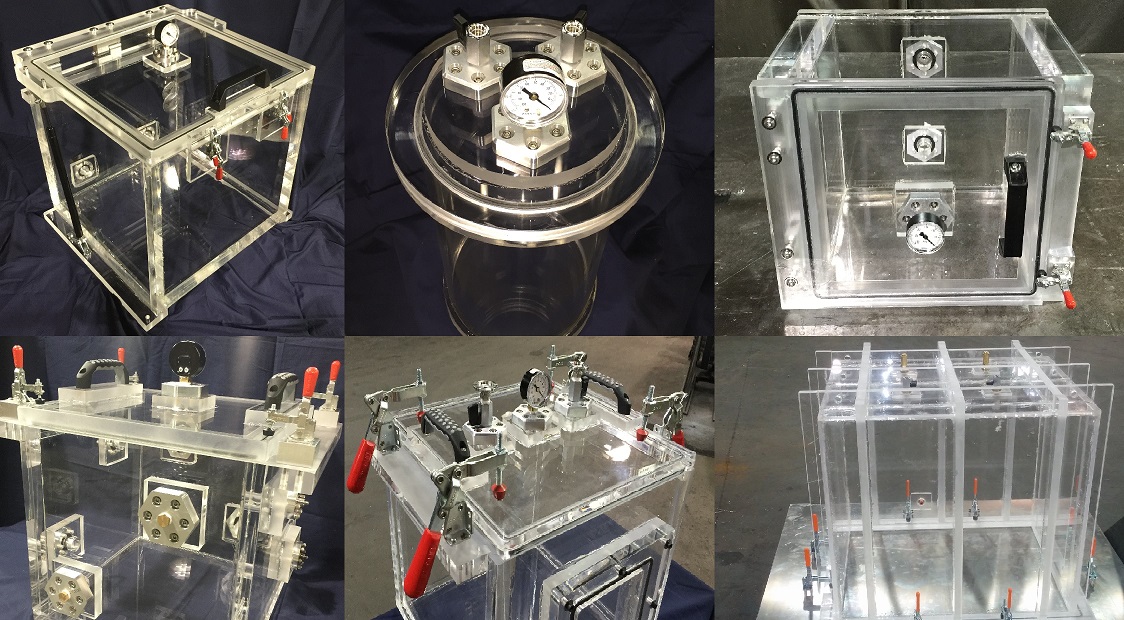

What you see here is a cylindrical vacuum chamber about 60 inch long and about 10 inch Inside Diameter. The rear of the chamber has the door clamped against the rear wall. We provided our client with the rear door for easier access to the chamber from the back. The front on the other hand, has a sealing plate that is specifically designed to have a double sealing O-Ring which seals again the sealing plate and against the inside of the Hi-Pot Cable. As soon as the Cable and the O-Ring are in place, the vacuum can be pulled and a pressure of 165 Torr is achieved within minutes. Now the cable can be tested for discharge and a safe airplane component can be successfully tested and made. You can see a video going a little bit more into detail about how this vacuum sealing mechanism works and how a part of the cable is used for testing purposes.

Video of the Setup

You may be interested in some of our other items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers