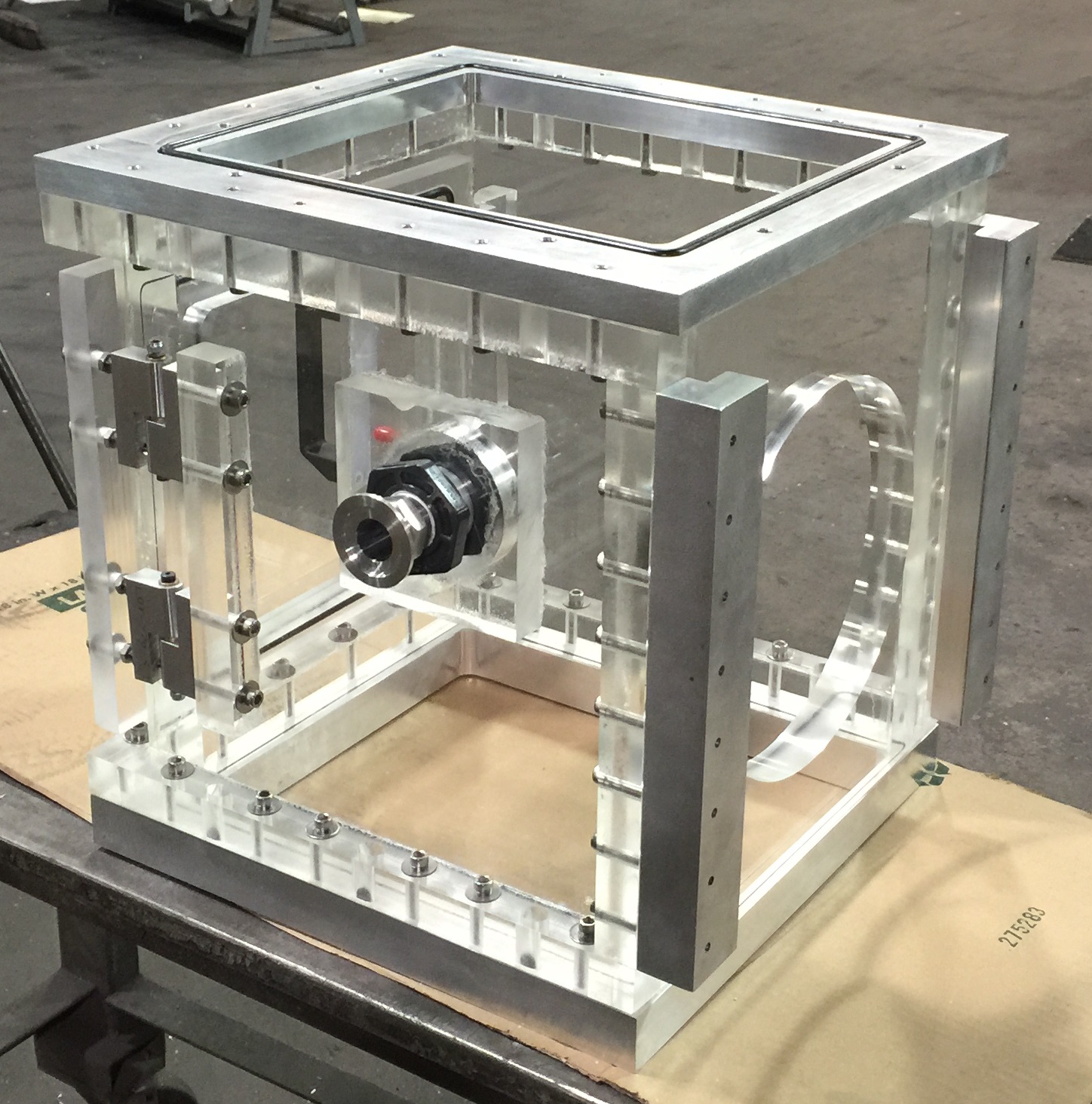

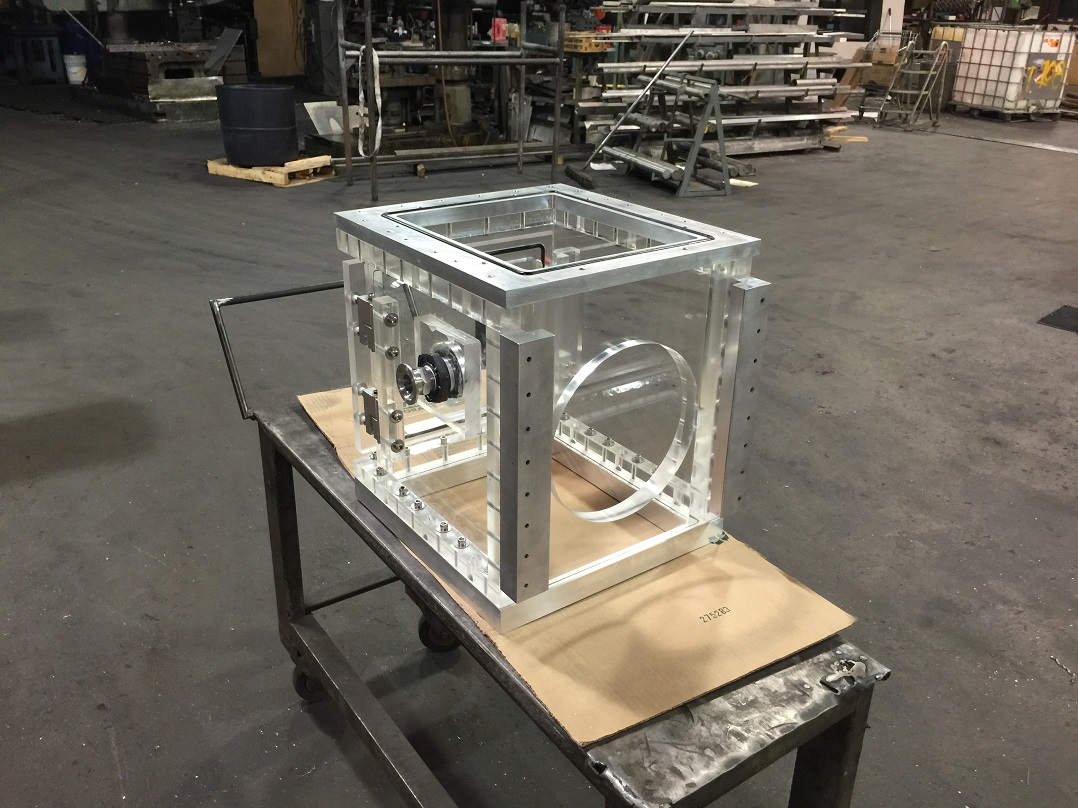

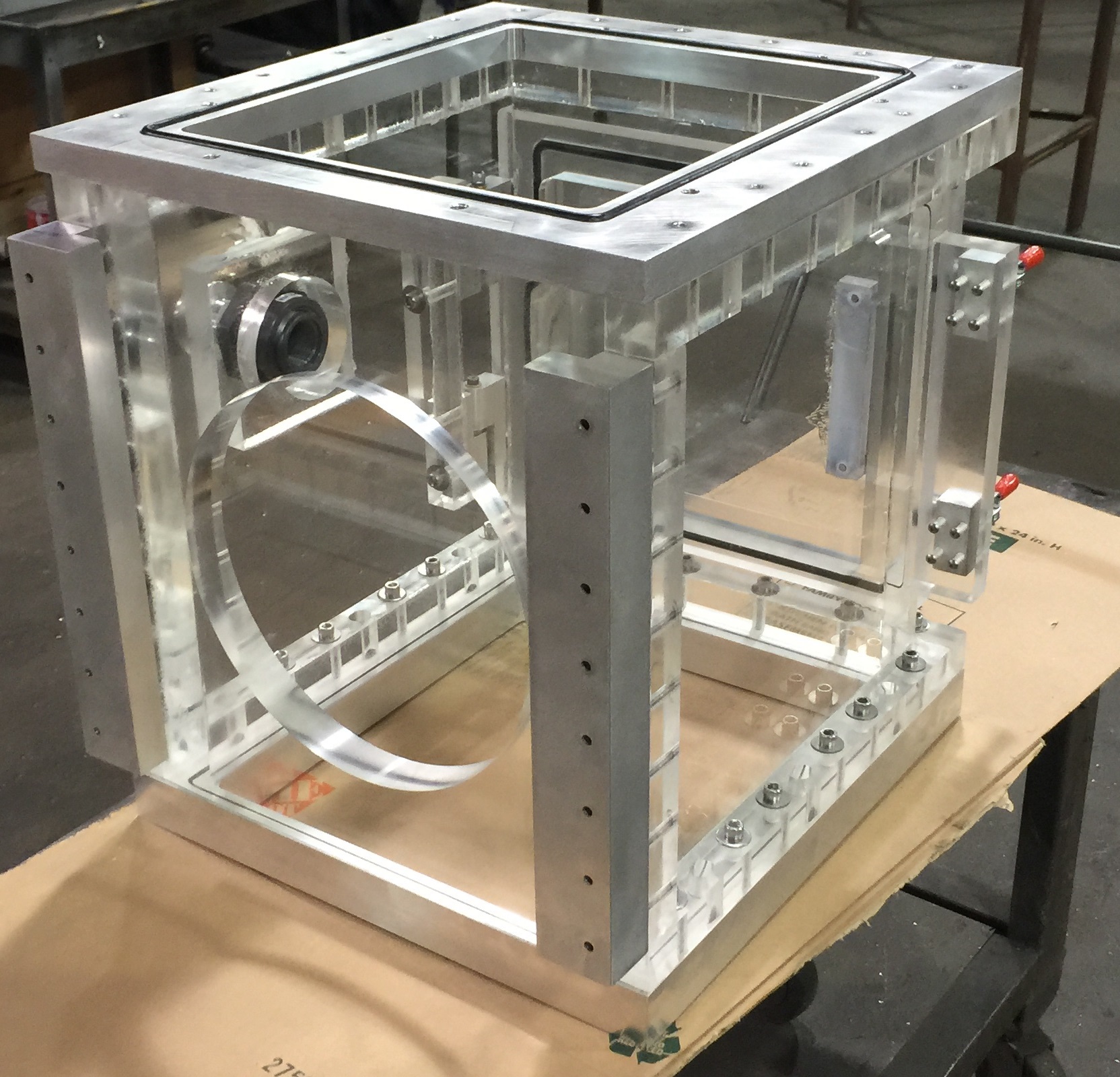

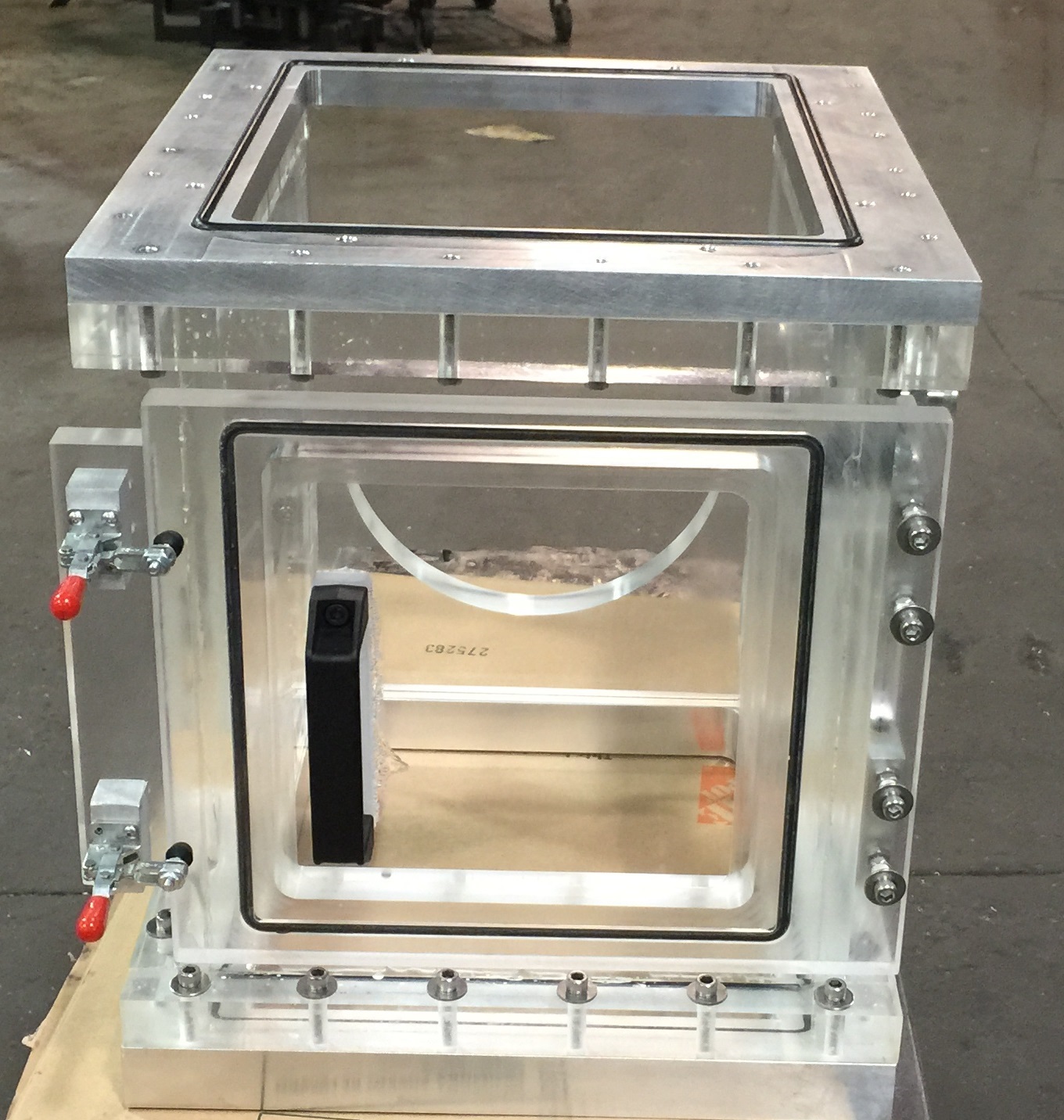

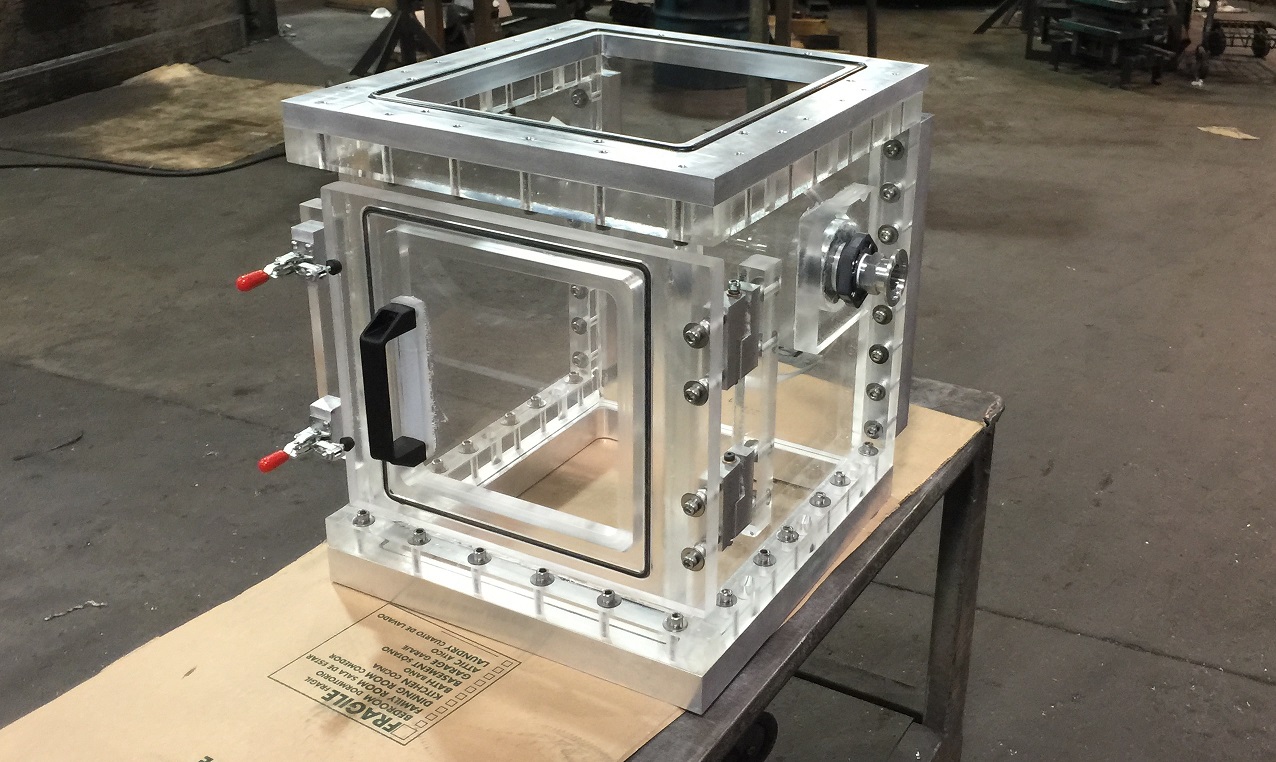

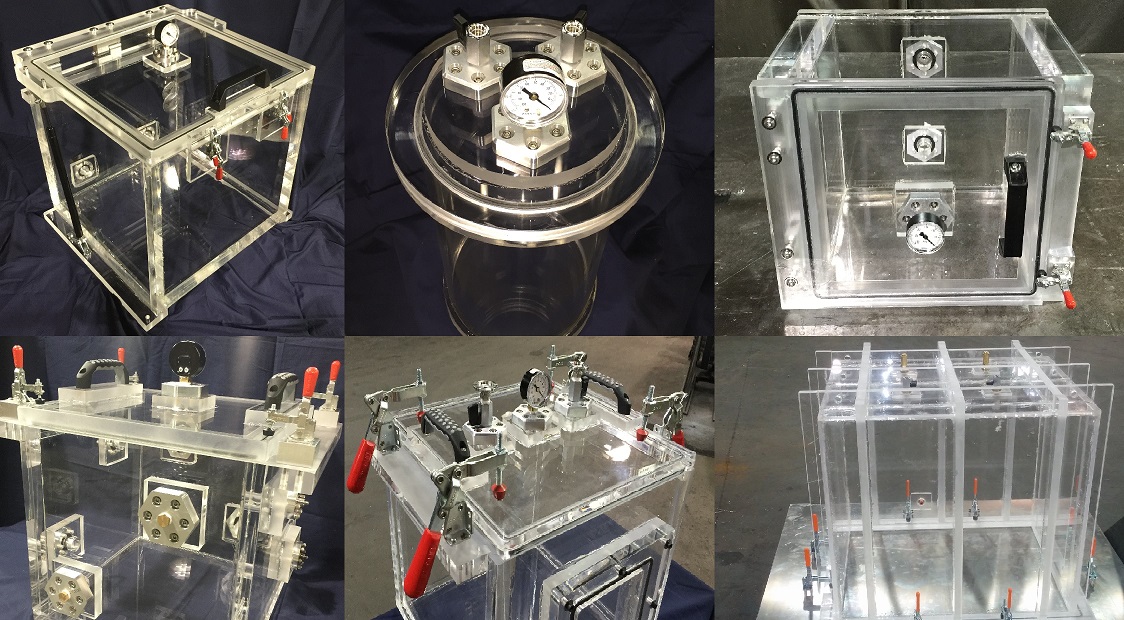

Chamber for Vacuum Extrusion System

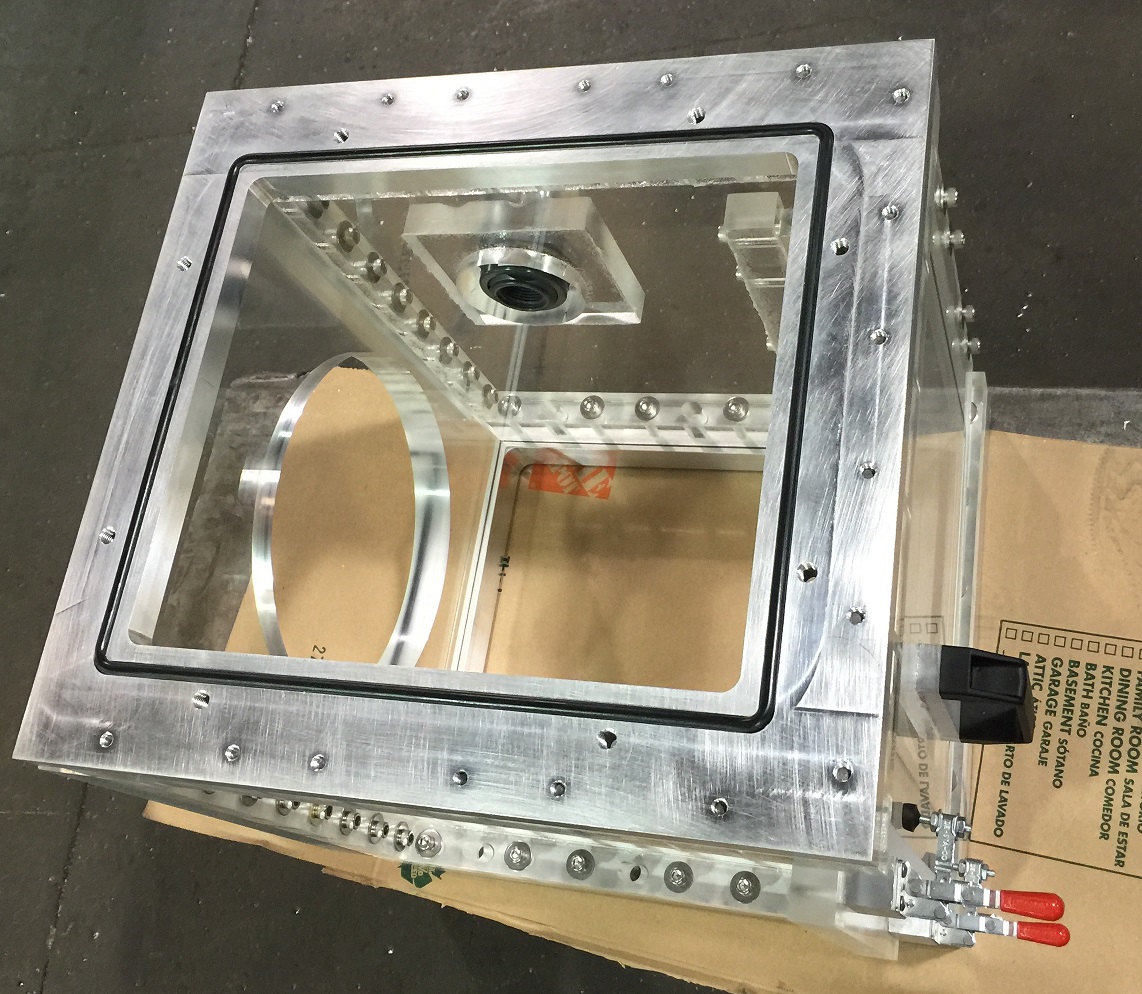

This is a custom acrylic vacuum chamber build for a high volume manufacturer of parts that are fabricated using vacuum extrusion techniques. The challenge was to build a vacuum chamber system which interfaced on 3 sides with various in-house extrusion equipment components in order to create a good vacuum seal. The bottom, the top, and on the rear of the chamber had to interfere with the vacuum extruder assembly. This was accomplished by incorporating a double gasket mechanism on the bottom and top and by incorporating a clamping mechanism on the rear. The top of the chamber interfaced with extrusion cutting equipment. The rear of the chamber interfaced with the vacuum extrusion die. The bottom of the chamber interfaced with the vacuum hopper.

The advantages of using an acrylic vacuum chamber in vacuum extrusion environments is that it allows for full visibility of the product. Additionally, a camera system can be added to the operation enabling fully visual inspection of the interior hence increasing throughput, quality, and safety.

On a personal note, this was a very tricky engineering problem because we were aiming to design a chamber which had to create a vacuum tight fit against three surfaces which were not completely perpendicular to each other due to wear and tear. This was accomplished by using a double gasket aluminum interface plate.

In the end, all went well, and looking back we have nothing but gratitude to this customer for giving us a chance to push ourselves beyond what we were comfortable doing - hence making us better engineers. This was a challenging and fun project; not only were we able solve a problem they were wrestling with for quite some time, we also made friends and connected with people on the other side of this country.

Video of the Extrusion Vacuum Chamber

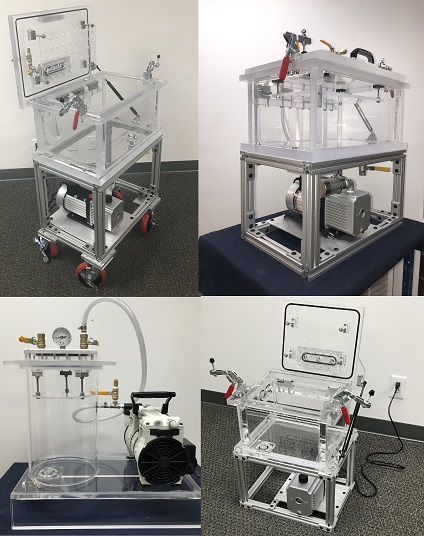

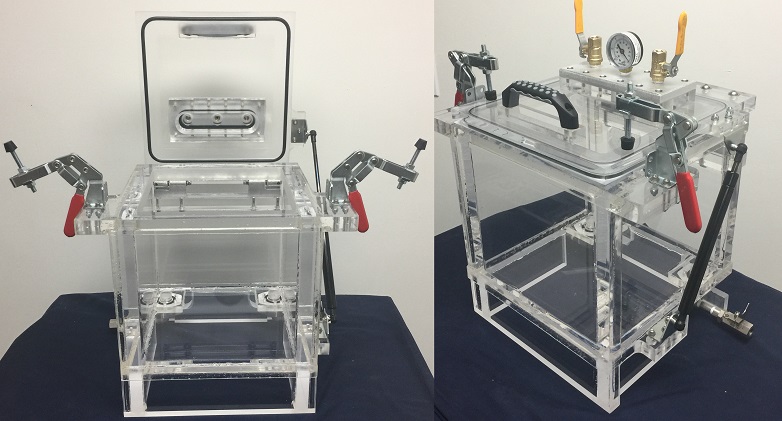

You may be interested in some of our other items

We make Robustly Designed and Quality Engineered Systems. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers