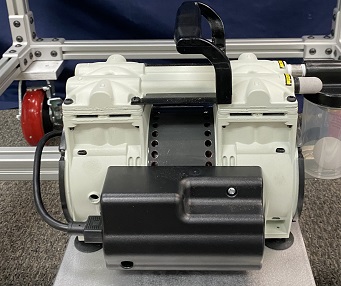

Wob-L Dry Vacuum Pump with Inlet Trap and Gauge, 230V 50Hz 1Ph, with CE mark, 60 Torr at 7.1 CFM

Product Specifications

Features

Description

Welch, Dry, Oil Free Vacuum Pump featuring WOB-L technology. This particular model number is 2585C-50. The free air flow rate is 7.1 CFM and the ultimate vacuum rating is 60 Torr or (27.9inHg of Vacuum). This Pump comes with a power cord and a user manual. This is a very popular vacuum pump among laboratories, educational institutions, pharma, and biotech industries due to the fact that this pump is low maintenance and and oil free (dry) which can be used in indoor and closed rooms and environments without the risk of oil contamination. It does not come with connection hardware you will need to connect this vacuum pump your vacuum system. The Intake Port Thread of this pump is a 1/4 inch FNPT. Connected to this Intake port is a barb hose fitting for the 3/16 inch ID vacuum hose. To connect this pump to you vacuum system, you have two choices:

1. You can either connect a reinforce vinyl hose with 3/16 ID to the already present Barb Fitting.

2. You can unscrew the Barb Fitting and screw on your own fitting. Sometimes going from 3/16 inch ID hose to 1/4 inch ID hose will decrease your pump-down times by a factor of about 1.5.

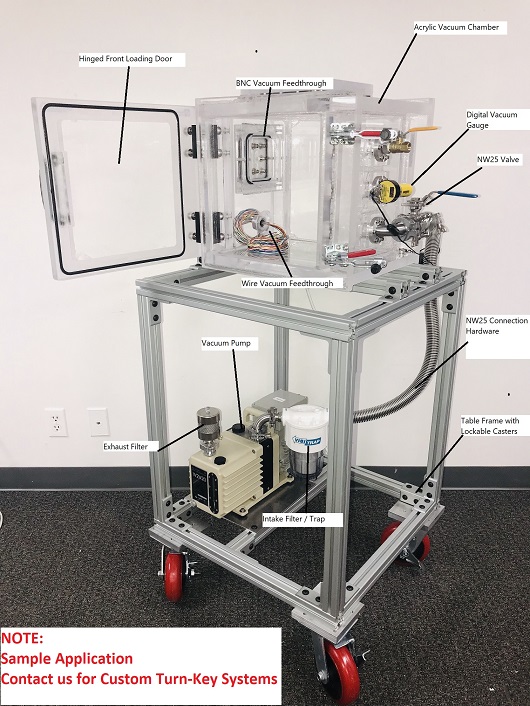

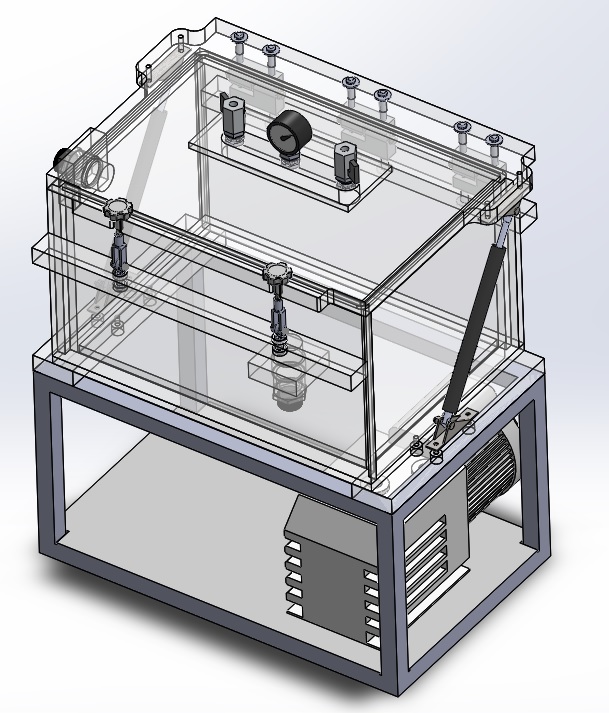

Some of our Popular Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.