This article will talk about how to test the seal integrity of food bars. You will understand what you will need to do in order to ensure good seal quality. This article covers the seal integrity testing of Breakfast bars, Chocolate candy bars, Crisped rice bars, Energy bars, Granola bars, Health bars, Protein bars, Fruit and Nut Bars, Meal Replacement Bars or any other food bar sealed with a flow wrapper.

Most food bars are sealed using a Flow Wrapper Machine. A flow wrapper is a continuous motion packaging equipment that creates a sealed food pouch from a single roll. As the food bar (or food product) travels down the conveyor belt, the packaging roll is unwound simultaneously. The edges are sealed to create the middle seal. Then the food product is inserted or pushed into the now created tube. A second heat sealer will seal off the bar and cut it, keep in mind that the rear seal of the first food bar is the front seal of the second bar. In the end you are left with a single food bar.

Why are food bars heat sealed?

In order to protect your product and your customers every single one of your food bars must be properly sealed. The purpose of hermetically sealing your food, thus providing a physical barrier, is to protect your products from microorganisms entering the food and to prevent oxygen from spoiling your products.

A bad seal will not only spoil or contaminate your products and put the end user at risk, it will also tarnish your business reputation; not to mention, cost you a lot of money. It is therefore of critical importance to hermetically seal your food bars.

How do you know that you have a good quality heat seal?

Now that you have a why, you must determine how you will test for heat seal integrity. The first step is to develop a goal of your seal testing procedure. The second step is to implement it.

To develop your goal, you must first determine what constitutes a good seal. What does it mean to have a good seal? Secondly, you must establish an acceptance criterion of your test. This means that you must determine and justify an acceptable failure rate. To do this, you must select a sample size of your test. As a standard, a good sample size is somewhere from 10 items to 50 items, tested every 30 minutes with a failure rate of 0.

What equipment is used to test the seal quality of food bars?

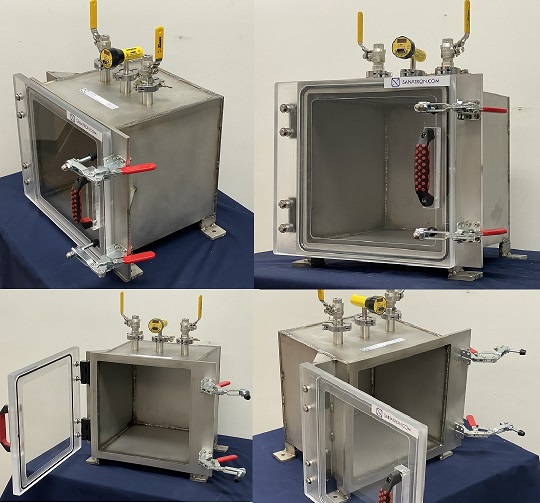

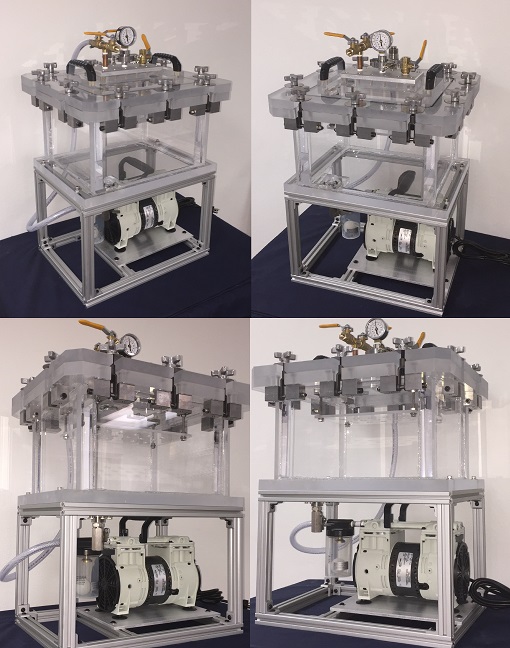

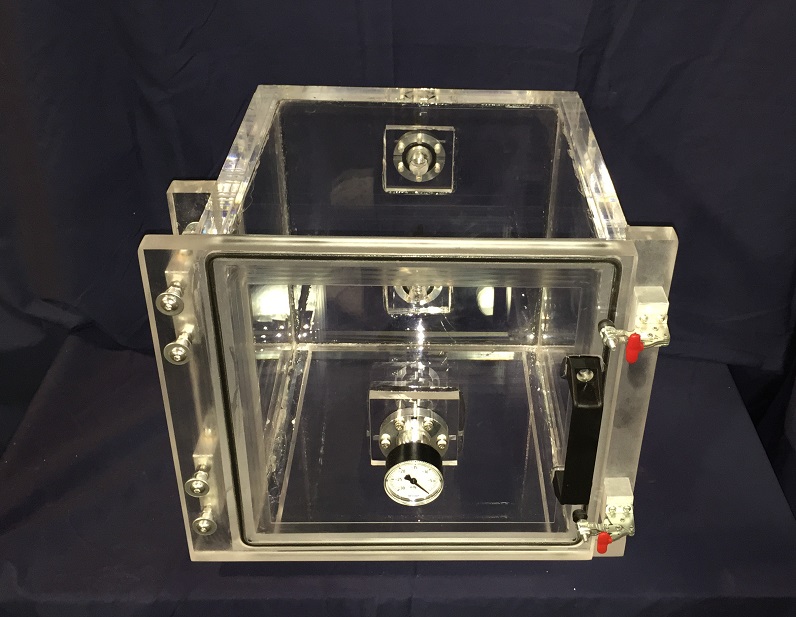

Food bars are mostly tested utilizing a Vacuum Bubble Leak Tester. A Vacuum Bubble Leak Tester is a machine which consists of a clear acrylic vacuum chamber and a vacuum pump. Before the test the clear acrylic vacuum chamber is filled with water. The heat-sealed food bar is submerged into the water. Many times, the food bar will float, this is because buoyancy is created due to the air inside the test specimen. The Vacuum Bubble Leak Tester will have a so-called package restraining mesh on the lid and once the lid is closed, the food bar will be pressed under water. Then vacuum is applied and the operator will be instructed to look for air bubbles emitting from the food bar.

As the vacuum is increased inside the clear vacuum chamber, the food bar will expand in volume. This is because the pressure outside of the food bar is lower which in turn will cause an inflation of the food bar.

See our Bubble Emission Leak Testing Systems Catalog

Vacuum Bubble Leak Tester is a Good Candidate

Vacuum Bubble Leak Tester is the ideal choice for testing food bars because it is a very inexpensive equipment. The test can be performed with little operator training and supervision in under one minute.

The Vacuum Bubble Leak Tester will help determine the leak location meaning that a pattern can be discovered. Additionally, the Vacuum Bubble Leak Test can also discover seal strength meaning if the packaged food bar seal bursts, you have a weak seal.

We have a thorough article on Bubble Leak Testing using Acrylic Vacuum Chambers that you are welcome to read more about.

Further Reading on Pacakge Testing

Bubble Leak Testing using an Acrylic Vacuum Chamber

Recommend Package Closure Integrity and Quality Testing Methods

References:

FDA.GOV: BAM: Examination of Flexible and Semirigid Food Containers for Integrity

Similar Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. What are you building? Take a look at the links below and discover some of the cool things we make.