How do you leak test Large Food Bags?

This is the same question a Large Food and Beverage Processor had asked themselves because they had need for a bubble leak testing system which could be used to detect presence of leaks in their large bags. Their requirements were to test several sized bags with the largest bag being 24 inches Wide by 12 inch Deep by 9 inches High. In addition to the bubble leak testing system, they also needed a way to dry the bags after the test.

Why is leak testing done on Large Food Bags?

It is very important to leak test large bags of food for several reasons. First, a leak in the bag, will decrease the shelf life of its contents. Second, a leak will cause the contents to go stale faster resulting in decreased quality. Third, a leak is a contamination risk as it allows for bacterial, viral, and fungi to enter the contents and spoil them. The damage caused by a leaking package is far beyond the damage to the product. There is also the potential risk of soiling of customer relations, not to mention the potential for health hazards.

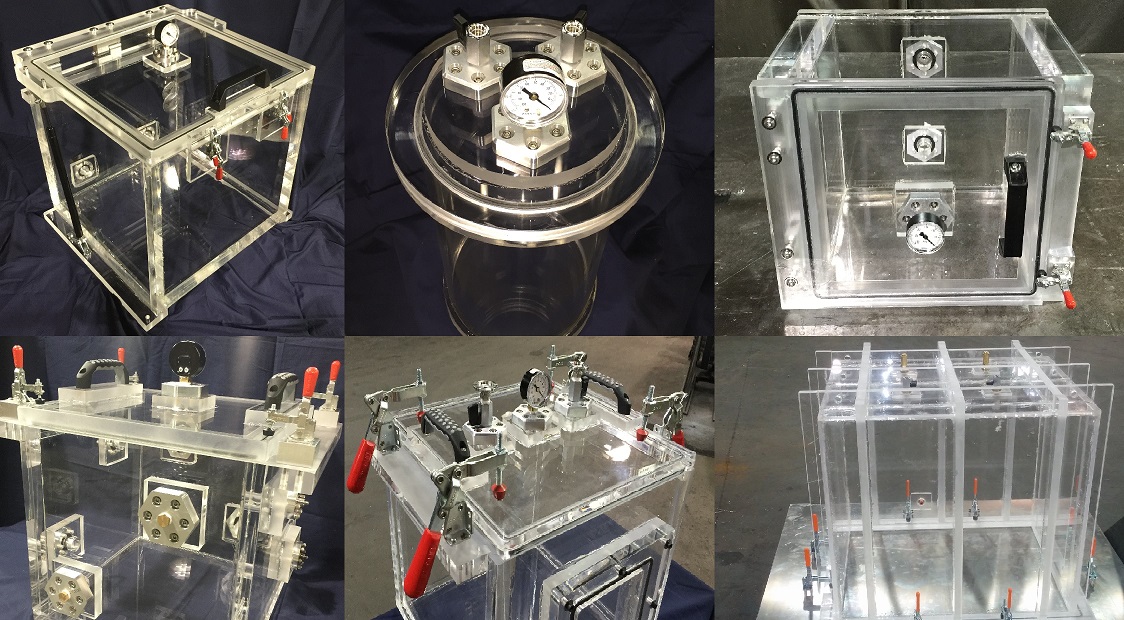

Fortunately, an Acrylic Bubble Emission Testing System is commonly used in the Food and Beverage industry to leak test large bags containing Hops, Soy, Corn, Wheat, or any other grain. Any bags that are non-porous and heat sealed and which required a full hermetic seal can be leak tested by a bubble leak tester.

About this Leak Testing System

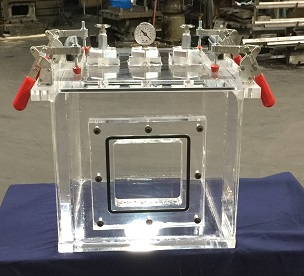

Since this leak testing system is operated indoor, an oil free vacuum pump is the recommended choice because the maintenance is minimal and there are no oil mist emissions from the vacuum pump. The inside dimensions of this Acrylic Vacuum Tank are 35 Wide x 18 Deep x 12 Hight, it has a Gas Spring to Support the Lid which is kept in place during the loading and unloading of the large test bag. To the right side of the tank, you can see the dry off sink, this is where the bags are dried off after they have been dunked for the leak test. The assembly is housed on a frame structure which connects the Leak Testing Tank, the Vacuum Pump, and the Dry-Off sink. It is a complete, fully assembled system – Just Add Water.

If you are interested in ordering this product, please Contact Us

Some of our Popular Items

We are an Engineering Excellence Company. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers