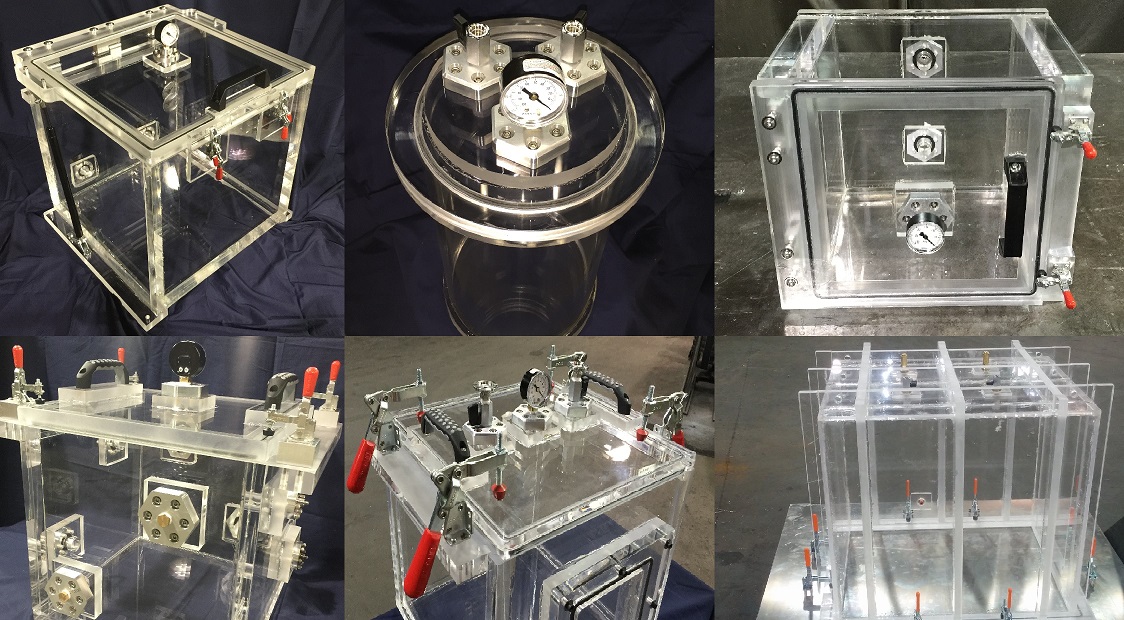

A wonderful company (more like one of the best companies in the world) which is currently involved with the research, development, and testing of high-altitude weather balloons, had a need for a vacuum chamber capable of achieving about 100 micro Torr (Micron) of ultimate Pressure for their testing environment. Fortunately, acrylic vacuum chambers are the perfect choice when it comes to Low, Rough, and Medium Vacuum.

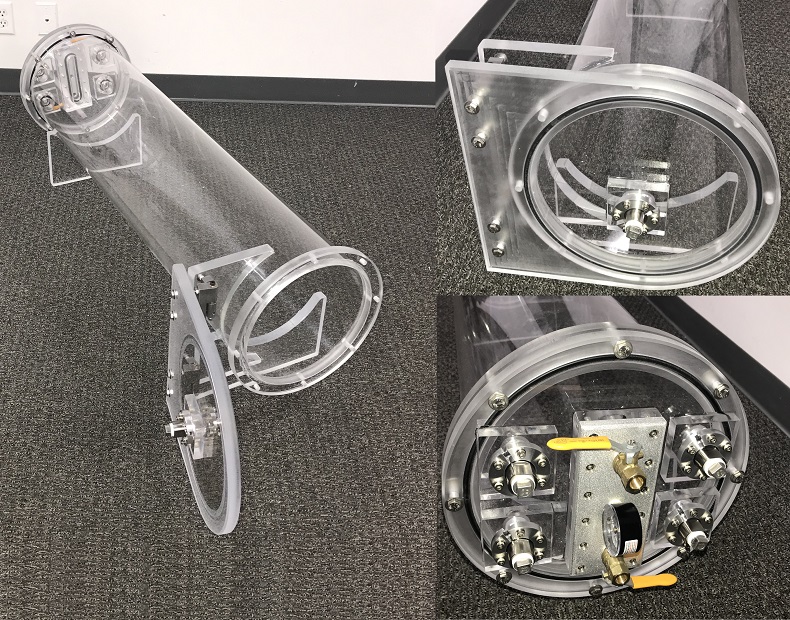

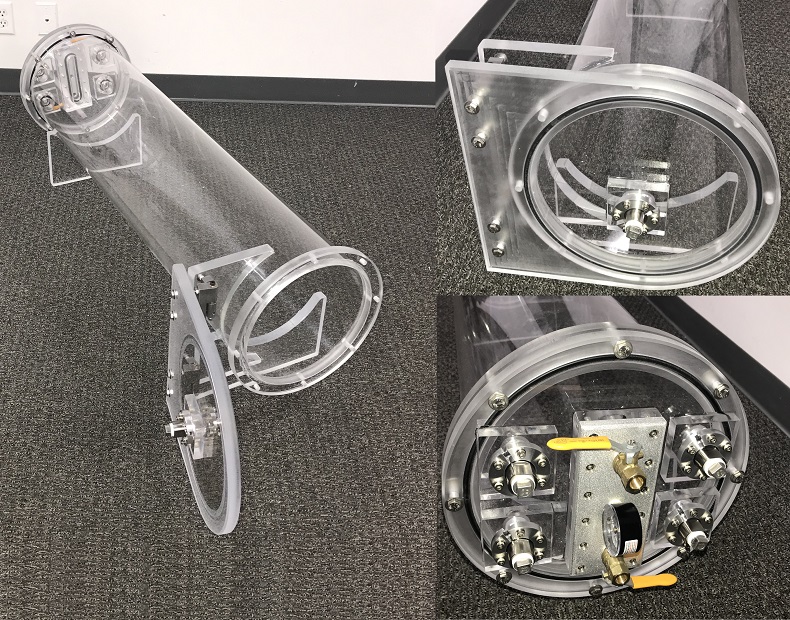

This horizontally placed, cylindrical, clear acrylic vacuum chamber is about 12 inches in diameter by about 50 inches long. It can be placed horizontally on a table top. The interior of this chamber is accessed by opening the door on the left side. The right wall is also removable.

The chamber is used for testing of weather balloons. Notice that the door on the left side is not latched or clamped. The reason for this is due to the risk of over pressurization. In the unlikely event of the weather balloon bursting during the test procedure, the contents of the balloon would expel into the vacuum chamber and rapidly increase pressure and over pressurize the vacuum chamber. A latched or clamped door would keep or contain the pressure and risk damaging the vacuum chamber.

This design allows for the chamber door to simply open if the pressure inside the chamber changed from negative to positive and quickly relieve any overpressure without the risk of damaging the vacuum chamber.

On the opposite side of the door, we provided a total of 4 x 1/2 NPT Ports (which are plugged of course), a dial vacuum gauge, and two 1/4-inch NPT Valves (one is the vacuum valve, the other is the venting valve). Additionally, the whole left wall can be removed by removing the 8 fasteners present.

One advantage of having a removable right wall is that our client can customize right wall and add any other vacuum components such as thermocouples, feedthroughs, power feedthroughs, even multipin or Sub-D connectors if they choose to do so. Another advantage is that this allows for multiple wall configuration plates that can be made specific to each of their experiment. Not to mention the ability to able to clean or remove anything stuck on the opposite wall of the door. Can you imagine the hassle having to clean it without the ability of wall removal? One would have to have a really long broom stick to reach that deep in there…

Contact Us if you are interested in having us build a custom vacuum chamber for you

Similar Items

We make Robustly Designed and Quality Engineered Systems. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers