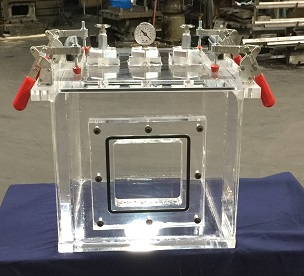

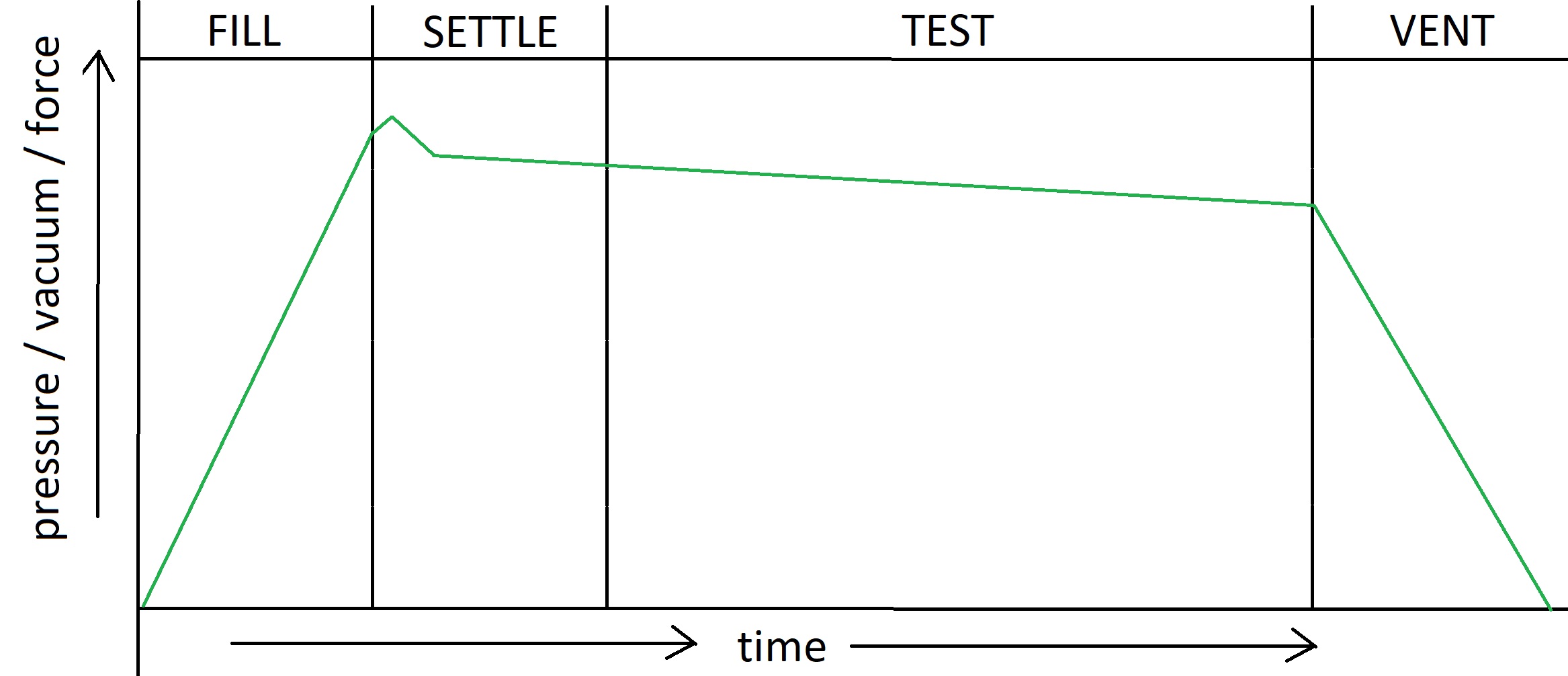

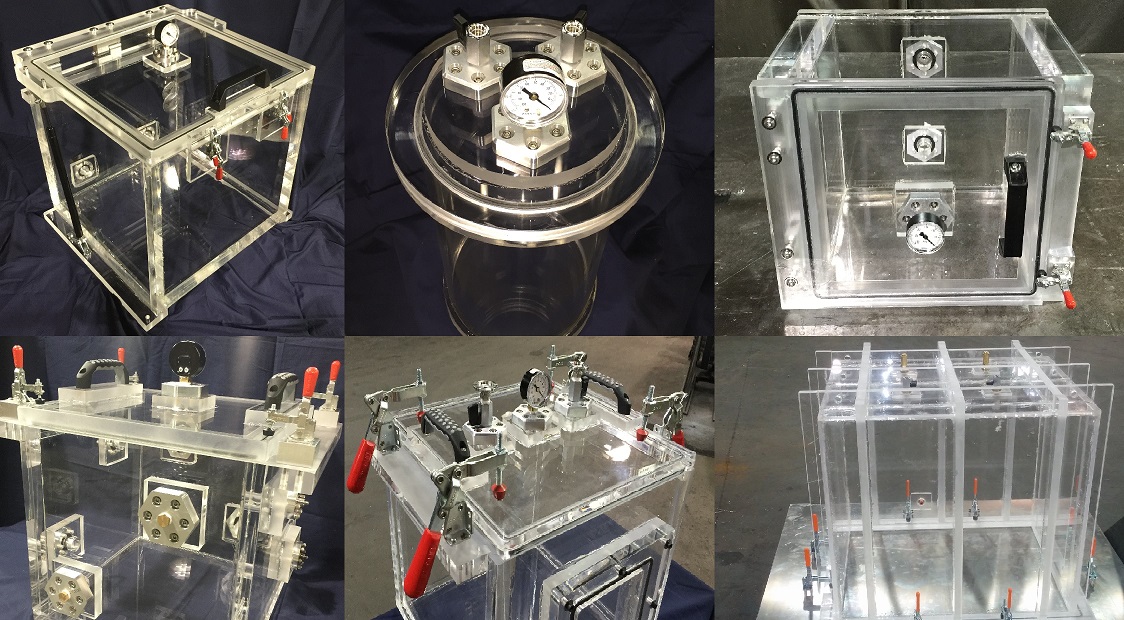

The ASTM D6653 or ASTM D6653M is a standard test used to determine how the effects of higher altitude will affect package integrity. As you know, altitude can be simulated inside a Vacuum Chamber by altering absolute pressure to correspond to a specific altitude.

The Yogurt Story: Why you should implement the ASTM D6653 Protocol?

There are many reasons to perform the ASTM D6653 one of the reasons is the “Yogurt Story”. This is one of our favorite failure stories. Well, we must keep things confidential but let’s just say that a Manufacturer of Dairy products located at a lower altitude was delivering a trailer load (40,000 lbs) of Yogurt cups and Pudding to a customer of theirs. Their customer is located at a higher altitude city right on the Rocky Mountains. As soon as their customer opened the trailer door to unload the Yogurt, they were terrified to see what had happened. It was the most horrendous sight! The yogurt and pudding oozed out of the cups and most of the seals were broken. It was summer and the smell of fresh Yogurt, Vanilla, Strawberries, and Chocolate quickly filled the customers warehouse.

As the driver walked over to see for himself, he mentioned that: “That’s where I have been hearing the popping sounds from, it’s the Yogurt… I thought it was my suspension” Right after he finished his sentence, the forklift driver started laughing uncontrollably, the supervisor came over to see what the laugh was all about and when the forklift operator told him, the supervisor started laughing too. The forklift operator took a picture of the trailer and shortly after placed it onto their “Receiving Wall of Shame”. The Dairy Product Manufacturer, on the other hand, did not find this story funny because they just had 40,000 lbs delivery of broken yogurt cups rejected.

This is where we were contacted by them. We were referred to them by a client of ours. As we did our investigation, we determined that they did not have proper heat seal integrity procedures for higher altitude, nor did they use the ASTM D6653 protocol as a guide for their high-altitude package testing because “They were not shipping their products by air”.

The ASTM 6653 test procedure should be implemented not only on packaging to be transported by air, but on all packages. If the packages are transported from east to west or vice versa, chances are that the shipment may reach altitudes of up to 12,000 ft. Just because products are not shipped by air, does not mean that these will not be exposed to the effects of higher altitudes. It is imperative that you incorporate the ASTM D6653 if you don’t want the yogurt story to happen to your packages.

Fortunately, it all worked out in the end because we were able to deliver an ASTM D6653 compliant test system. And today it is just a funny story for the Shipper as well as the Receiver, but it was not as funny at the time it was happening.

In conclusion, if you are transporting products across the country and a good seal is important, contact us now so that you don’t have to live through the “Yogurt Story” with your products.