Microfluidic Testing using an acrylic vacuum chamber

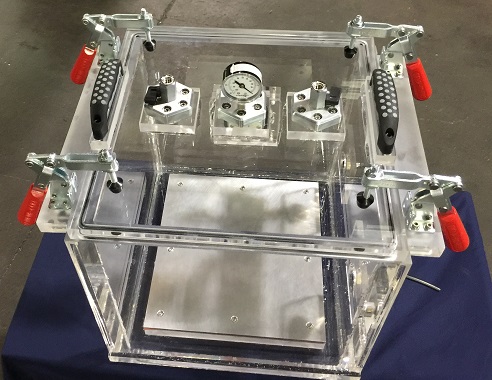

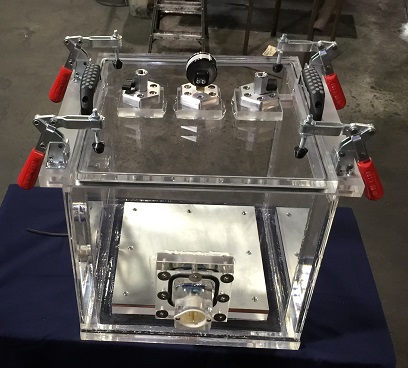

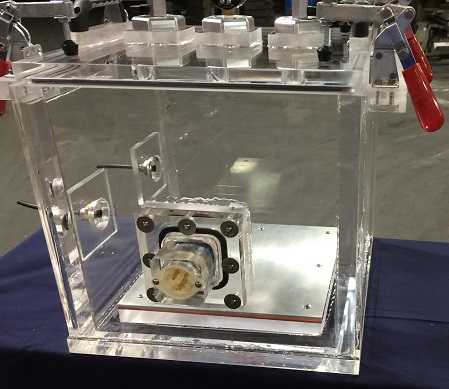

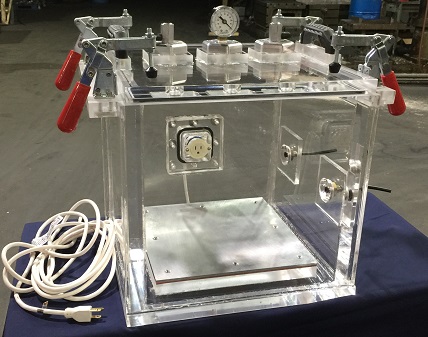

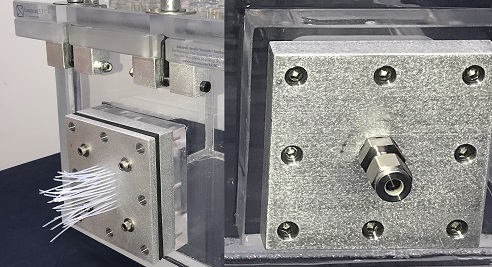

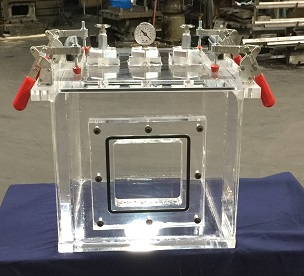

Our client performs a wide array of microfluidic testing in their laboratory. The requirements were 1. to install injection ports which are connected to a syringe pump outside of the chamber, 2. A gas port to pump gas such as carbon dioxide, helium, or argon into the specimen, 3. an electric feedthrough port in order to connect a heat plate and heat the sample inside the chamber during vacuum tests.

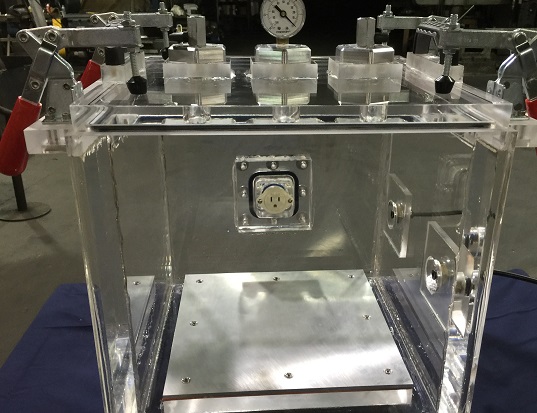

This was a custom chamber to which we added two feedthrough ports and an NEMA 5-15R power outlet (The same used in many US homes to power basic household appliances such as TV or a microwave)

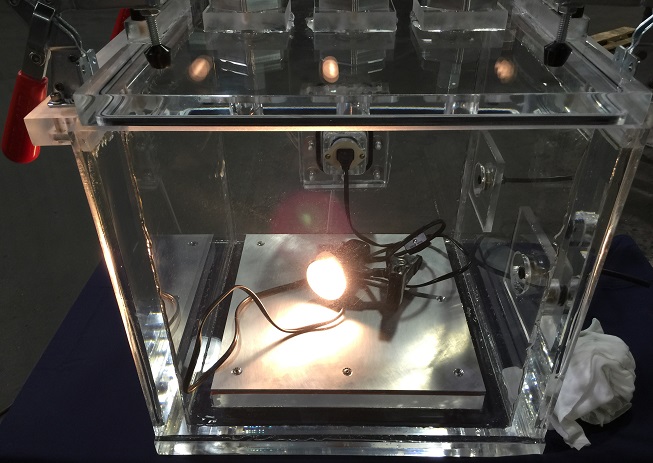

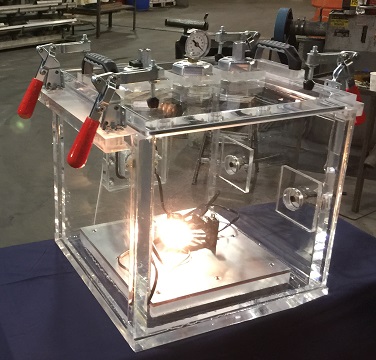

The final design also included an aluminum base plate along with a heat insulator beneath to protect the bottom chamber wall from heat damage. Take a look at the light bulb being turned on as we pull a full vacuum on this chamber.

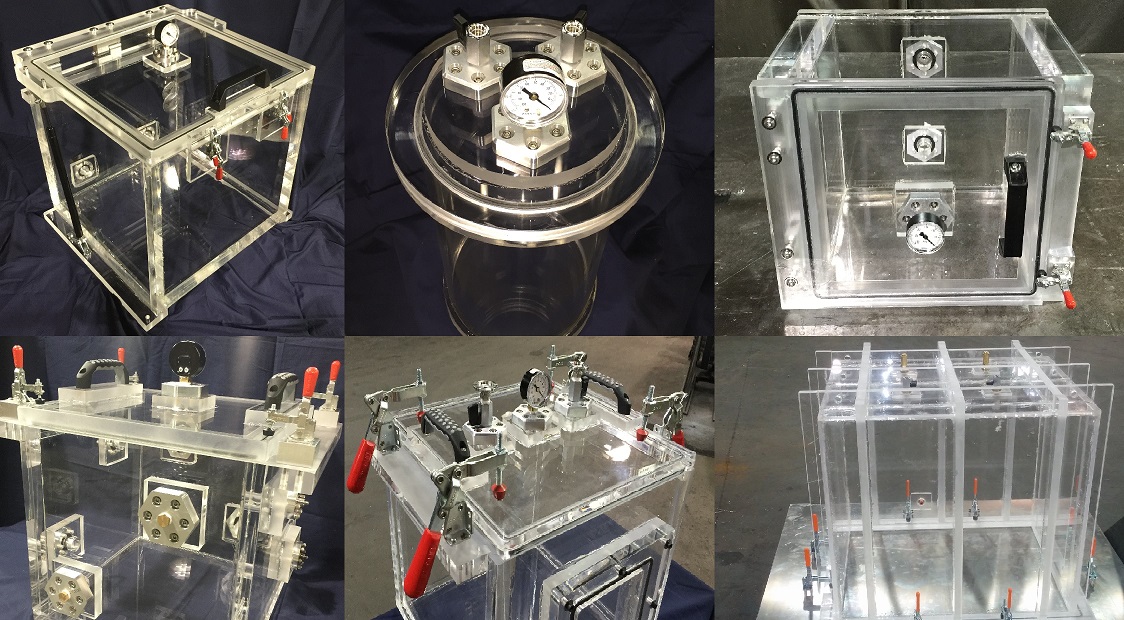

Did you know that we carry a many more products?

We make Robustly Designed and Quality Engineered Systems. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers