High Capacity Diaphragm PTFE Vacuum Pump, Model 2054, 230V, 6 Torr, 3.4 CFM

Product Specifications

Features

Description

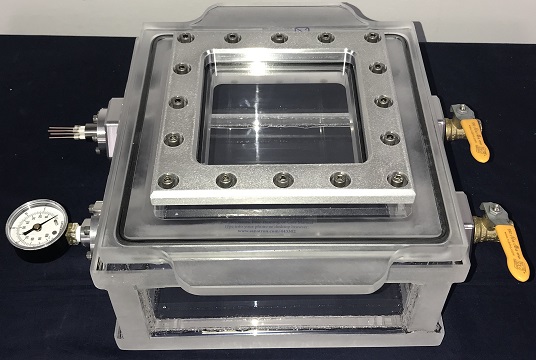

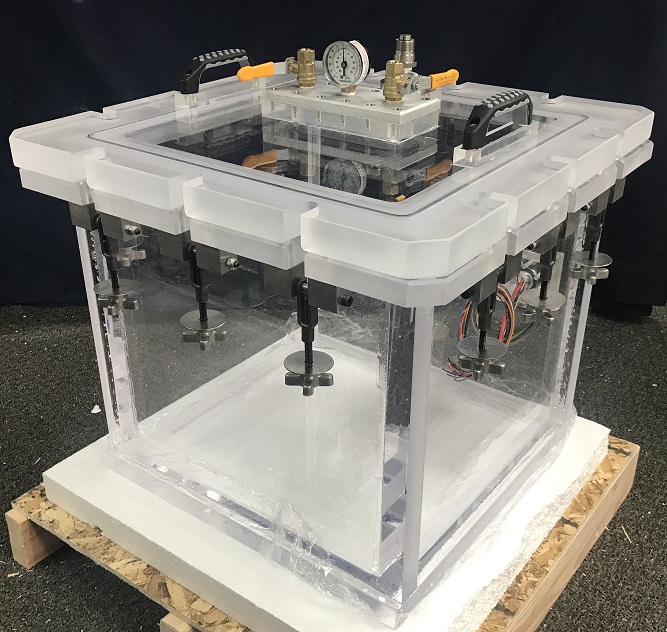

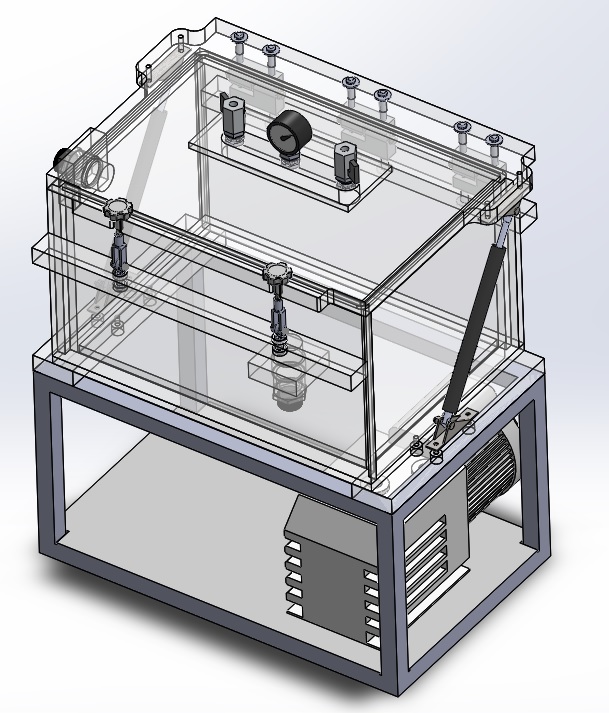

Welch DryFast Collegiate Diaphragm Vacuum Pump, Model 2054C-02, maximum vacuum 6 Torr and 3.4 CFM flowrate. Diaphragm Vacuum Pumps use a flexible expanding pocked, one directional (one-way) valves, and a lifting mechanism such as a rocking piston to expand and collapse the diaphragm pocket and move gas. This gas movement is what creates the vacuum. This particular Diaphragm Vacuum pump uses chemically resistant fluorocarbon materials in the construction of the pump components; this results in a vacuum pump that is highly resistant to chemicals and chemical attacks from corrosive liquids and vapors, acids, bases, alcohols, solvents, and thinners. This feature makes this particular vacuum pump a popular choice in Laboratory Applications.

Some of the advantages and features of this vacuum pump are chemical resistance, Oil-Free, no need for lubrication, and no need for maintenance, the vacuum is adjustable and high flow. Common applications include but are not limited to: Vacuum filtration, SPE(Solid Phase Extractions), Rotary evaporation, Rotary Evap of low and high volatile solvents, Vacuum ovens, Automated systems, Aspiration, DNA pelleting, Centrifugal concentrators, Multiple user filtration / utility vacuum network.

PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Note: Purchase of this pump is subject to End Use verification. A Certification form will be sent to you.

We have many more resources on our website that you should check out

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). You should check out some of our other items we carry; click on the links below.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.