There are many components which react adversely to air. Silicon Wafers are one example. Other examples include Silicon Based Sensors or Gallium Based Detectors. Conversely, medical devices and products may also have a need to be stored either in a vacuum environment or an oxygen free environment.

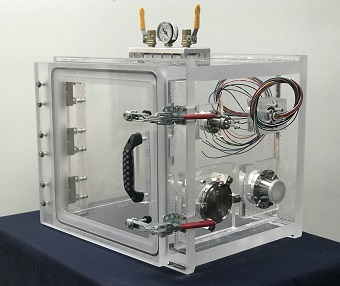

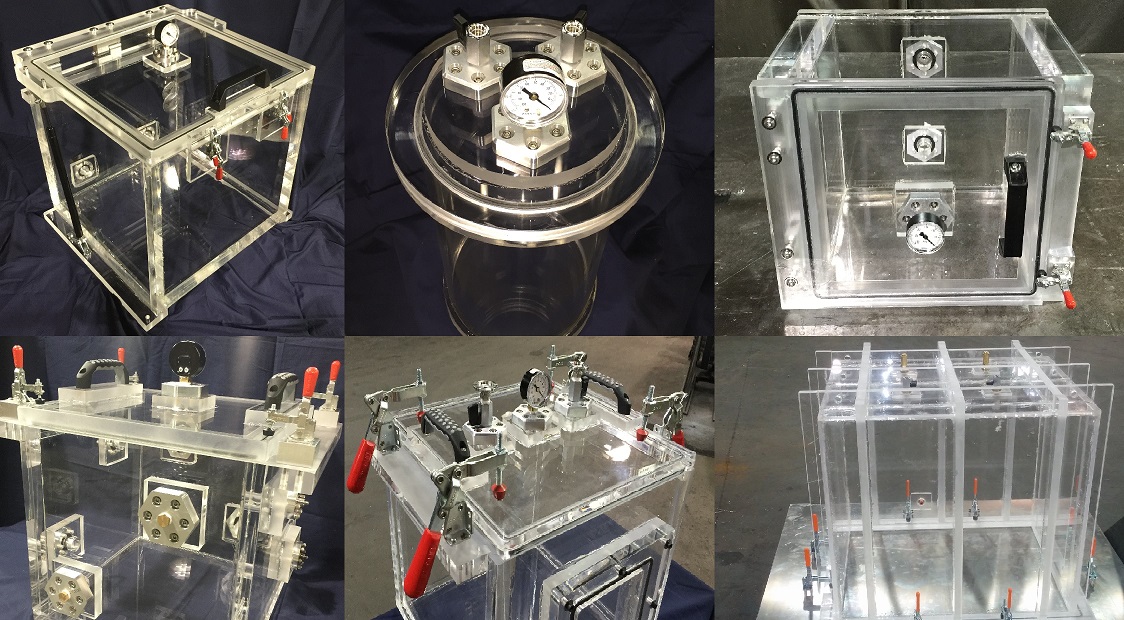

This particular system was envisioned, designed, and made for a Medical Device Manufacturer who also builds Sensitive Sensors. Our Acrylic Vacuum Chamber had to be a multi-use chamber. The requirements were for our chamber to have full vacuum capabilities of less than 5 Torr and capable of 5 psi of overpressure. The chamber was used to vacuum store medical device components between manufacturing process steps between batches. Conversely, there was also a need to store Silicon Based Nano sensors inside a pressurized chamber filled with nitrogen only. The vacuum chamber was evacuated several times and filled with nitrogen. Finally, the Silicon Based Nano-sensors were placed into the chamber. Finally, the chamber was now pressurized up to 5psig. The overpressure prevented any gas permeation from the outside towards the inside because the air was pushed out. This eliminated the risk of contamination.

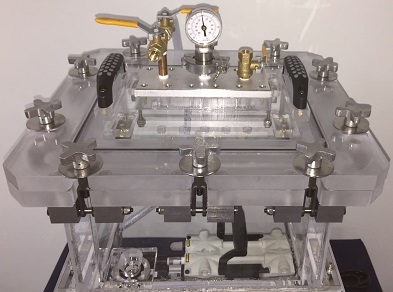

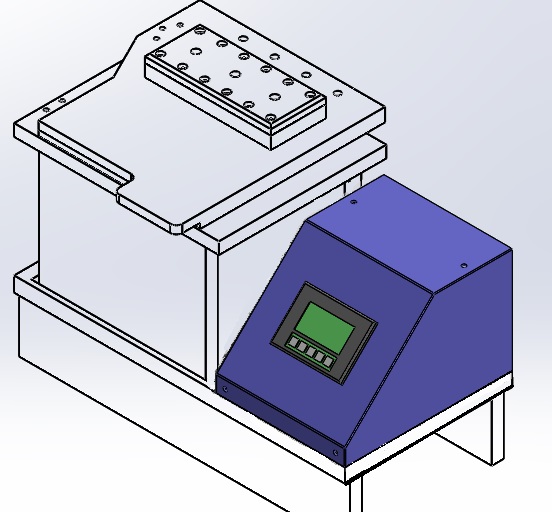

What you are looking at is a small vacuum chamber (about 12 inch wide x 12inch deep x 6 inch high) that is able to go to 5 Torr of absolute pressure during vacuum operations and 5 psi of positive pressure during overpressure nitrogen storage. You can see the thumb screws that are used to clamp the O-Ring against the acrylic chamber in order to keep an air tight seal. You can also see the vacuum dial gauge and vacuum valves. It’s a bit harder to see, but there is an Oil Free Vacuum Pump present below the vacuum chamber. There is also another valve that is present on the bottom wall of the chamber. This system is often used as a multi purposed system because it allows vacuum and pressure applications simultaneously.

Are you looking to store your products inside a vacuum or an oxygen free chamber? What about overpressure nitrogen storage? Contact Us today to discover how we can be of service to you.

We have many more resources on our website that you should check out

We are an Engineering Excellence Company. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers