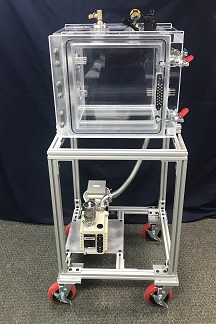

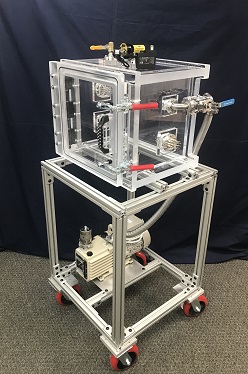

Portable Vacuum Chamber and Pump System, 20 in Front Door, Acrylic Chamber, 7.1 CFM Oil Free Dry Pump

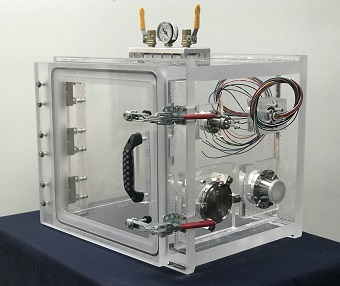

Additional Vacuum Chamber, Pump, or Controller Images

Check out some of our portable vacuum chamber and pump systems. All our vacuum chambers, vacuum controller, vacuum systems, or anything else that we make can be customized to your requirements and specifications. Contact us if to learn how we can build you a fantastic vacuum system.

Product Specifications

Features

Description

Our portable vacuum chamber and pump systems consist of a Robustly Designed Vacuum Chamber, a Prudently Sourced Vacuum Pump, Connection Hardware, and a Portable (cart/skid) Table Structure on Lockable Casters. A Quality Built Vacuum Chamber can be a bit tough to move around, which is why we have placed it onto a portable frame structure. This is fully assembled vacuum system, quality tested, and ready to go. The vacuum chamber is a front door loading, 10 inch acrylic vacuum chamber, the pump is a standard duty, 3.5 CFM, Oil Free Dry Piston Vacuum Pump with (runs dry oil free and with minimum maintenance), the connection hardware is a 1/4 inch NPT valve with a vinyl tube, all placed onto a portable frame structure with lockable swivel casters that allow you to freely move this assembly across your facility. On a flat surface this system is easily moved and once you get it into place, all you have to do is lock the swivel casters and it is in place.

Never again will you have to chase down several different vendors, deal with emailing and calling back and forth, in order to get your vacuum system in parts which you will have to time consumingly assemble yourself. We already did all the sourcing, assembly, and quality testing. In fact, our Portable Vacuum System is the only viable choice. Several years, dollars, and tears have been spent on sourcing, optimizing, testing, and reiterating the best Portable Vacuum System that we are happy to offer to you.

We have optimized this Portable Vacuum System for Quality, Performance and Cost. Fortunately, we can customize your vacuum chamber to any size. We can add any type of vacuum pump of your preference; just let us know. Furthermore, if you need additional customizations such as adding wires, thermocouples, or other feedthroughs, please contact us to find out how we can help.

Did you know that we carry a many more products?

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.