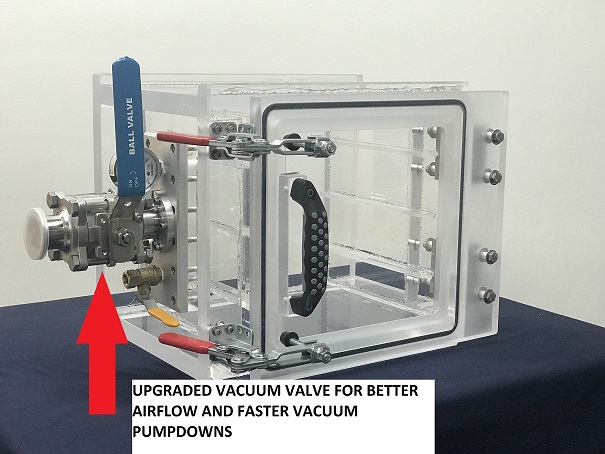

Every one of our acrylic vacuum chambers comes with 2 x 1/4 inch NPT Valves as a standard These are included without any extra cost to you. However, you may need to change or upgrade the valves. Fortunately, upgrading your vacuum valve is very simple to do when it comes to acrylic vacuum chambers. There are several reasons why you would want to upgrade your vacuum valve.

The first reason is that you may need a different thread or fitting. Perhaps you are connecting your chamber to a push to connect fitting. Or, you are using different connection hardware that does not connect to the standard NPT.

The second reason is that you may want to change the valve material. Our standard vacuum and venting valves are made from brass. There are some applications which require a different type of material. We have had several of our clients request the valves to be upgraded to stainless steel.

The third, and the most important reason to upgrade your vacuum valve is to improve the vacuum pumpdown performance. All things being equal, the 1/4 inch NPT valve has a cross section that is almost 10 times smaller than the cross section of the NW40 valve. This translates into a tremendous improvement in vacuum pump down performance.

To fundamentally understand why the pumpdown performance is drastically improved with a larger vacuum valve, we must go into the molecular level. When the vacuum pump is running it is essentially removing the air molecules from the acrylic vacuum chamber. There is nothing that “grabs” the air molecules per se. The only way the air is removed from the vacuum chamber is through diffusion; the air molecules move from a higher concentration (vacuum chamber) to a lower concentration (vacuum pump). According to Kinetic Theory of Gasses, air molecules randomly bounce against the walls of the vacuum chamber and each other. The only way vacuum can be achieved is if the air molecule inside the chamber passes through the cross section of the vacuum valve and flies forward towards the vacuum pump. If the cross section is larger, there will be a higher chance for that air molecule to hit the vacuum valve and move towards the vacuum pump.

Now that you understand why it is more beneficial to upgrade your vacuum valve, you can select the following valves:

1/4 inch NPT Stainless Steel, 3/8 NPT Brass or Stainless Steel, 1/2 inch NPT Brass or Stainless Steel, NW16 Valve, NW25, and NW40 Valve. Keep in mind that you will need the appropriate connection hardware for your corresponding valve. Please let us know which valve you would prefer and we can help you source the connection hardware. All industrial Vacuum Pump made by Leybolt, Edwards, Welch, and Pfeifer Vacuum most likely come with either an NW25 or NW 40 inlet port which can be conveniently connected to your newly upgraded vacuum valve.

Generally speaking, you do not need to upgrade both valves, only the vacuum valve so that you can connect it to the vacuum pump.

Keep in mind that you can also add an additional valve to your chamber. One of the reasons an additional valve is added to the vacuum chamber is to create a small airflow across an instrument inside the vacuum chamber.

Reach Out to Us to inquire more about Vacuum Valves and how these can make a difference in your pumpdown speed.